Engine Services

What is a "World Class Engine"?

Peak Power? Of course! In addition, it must produce amazing low and midrange. To be truly World Class, it must also be durable!

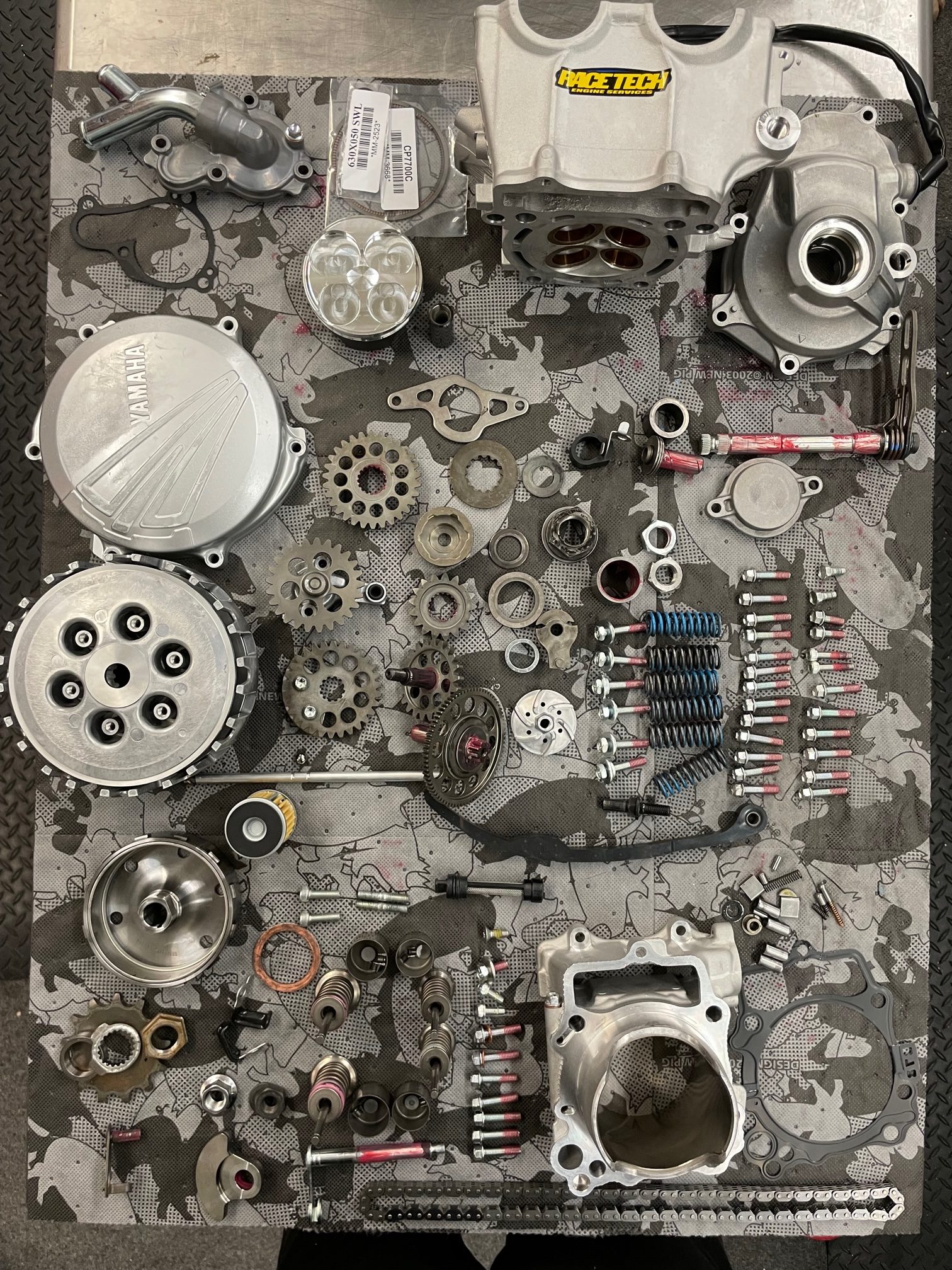

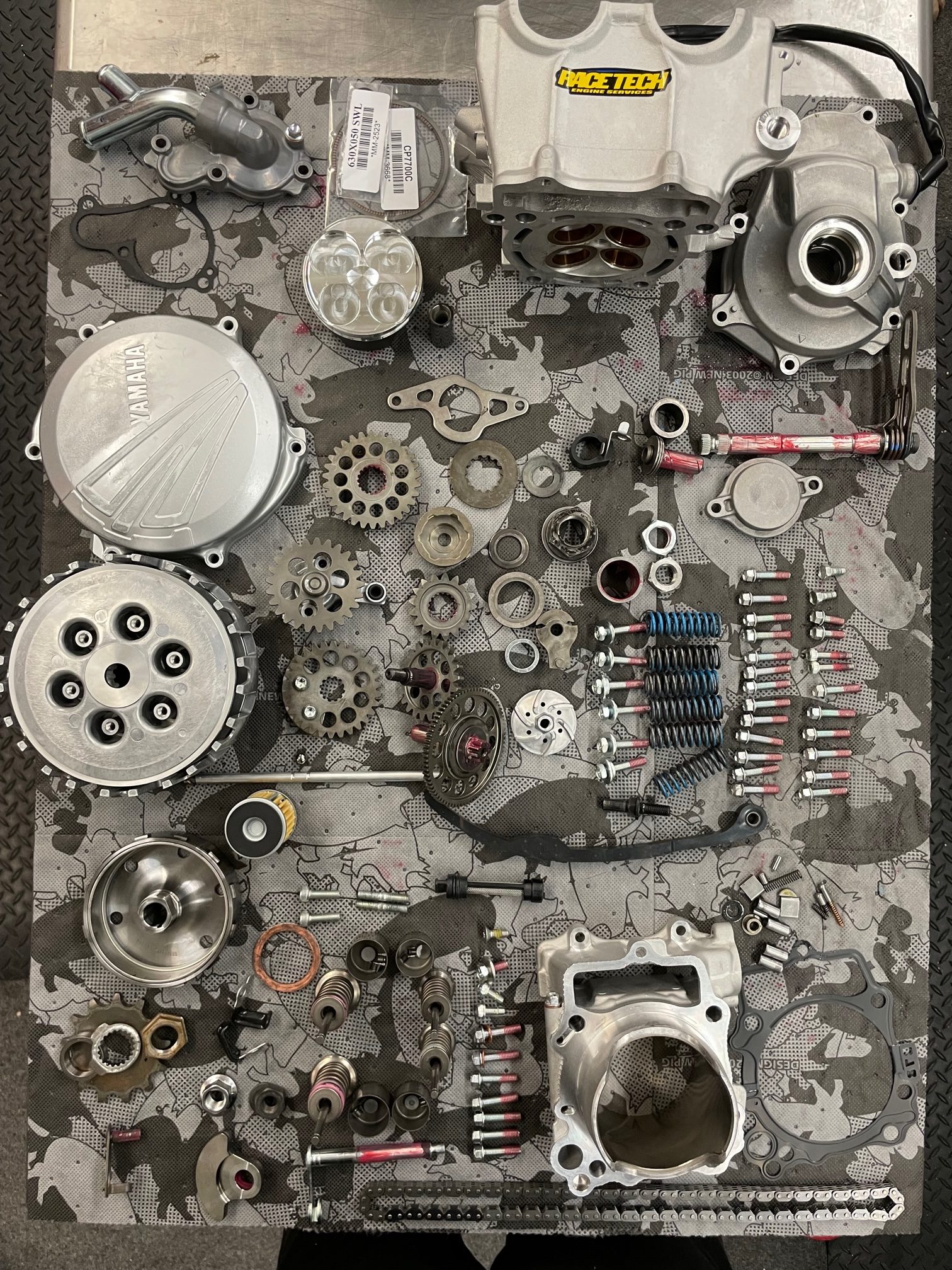

Building a World Class Engine requires state-of-the-art equipment and experienced, knowledgeable technicians. Race Tech provides quality, precision engine services for all engine builders, using the best equipment and processes in the industry.

The staff at Race Tech has over 65 years of championship-winning engine building and tuning experience formally educated by the world's most renowned engineers.

RT Power Plan™ - Do an Engine Search and follow the Plan. You can build your own World Class Engine.

Please do not send complete engines. Components only (i.e. head, cylinder, crank).

RACE TECH POWER PLAN™

Race Tech Power Plan™

Developing the best combination of porting, cam timing, mapping, and related components to build "World Class" engines is a painstaking process. Race Tech has spent an impressive number of hours doing R&D on the Flow Bench, Dyno, Rottler EM69P CNC, and at the Track.

The Race Tech Power Plan™ is a list of components that, when assembled, will produce impressive power, powerband AND reliability. If you follow the RT Power Plan™ and assemble the engine correctly you can build an engine capable of competing with anything in the world.

Includes recommendations for:

4-Stroke Engines

- Head Porting Type>Full Porting with possible addition of Epoxy to improve bottom-end power and throttle response

- Valve Job Type>5-Angle Radius Valve Job

- Cam and/or Cam Timing Changes

- Piston Manufacturer and Compression Ratio

- Valves or Valve Mod

- Valve Seats (for performance and/or reliability)

- Valve Guides (if there is an issue with stock)

- Valve Springs

- ECU and RT Mapping (for Race Gas and Pump Gas)

- Exhaust Pipe

- Also listed are model specific concerns

- If not included in the RT Power Plan, stock is recommended

2-Stroke Engines

- Porting

- Head Mod

- Piston

- Exhaust Pipe

Additional Care - many engines have reported areas of concern for reliability. For example some engines have weak timing chains. Known items are listed in the Additional Care line of the Engine Product Search.

To view the Race Tech Power Plan do an Engine Search

Engine modifications are for RACING ONLY! Not for highway (DOT) use.

CNC HEAD PORTING

Head Porting - 4 Stroke Engines

Engine modification is for RACING ONLY! Not for highway (DOT) use.

3 Types of Porting

Race Tech's head porting provides an increase in flow and velocity to gain both powerband and peak horsepower. Race Tech porting is developed using a combination of flow bench, dyno and track testing data.

A Valve Job is required with porting.

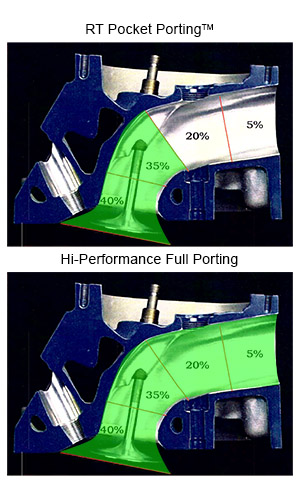

1. Race Tech Pocket Porting

Race Tech's innovative Pocket Porting provides 75% of the flow and velocity gains available while maintaining a great price point. If you look at the two graphics at the left what it is showing is the importance of the four sections of the port. Notice that 40% of the gains possible are very close to the valve seat opening. A whopping 75% of the total potential is covered only slightly further down the port (40% plus 35%). By focusing on these areas we can provide the best bang-for-the-buck.

2. Hi-Performance Full Porting

Full Porting increases flow and velocity for maximum efficiency (from flow bench data). This option is available when cost is no object and you are looking for the best available. The entire port is addressed.

In some cases extensive modification of the combustion chamber is required.

3. Hi-Performance Full Porting - with EPOXY

Certain models benefit greatly by making the intake port runners smaller. When the ports are too large the air velocity slows down and low-end, mid-range and throttle response are negatively affected.

Adding epoxy to make the port smaller increases velocity. On these models low and mid-range power are improved while actually increasing top-end. On models where this is offered, this modification creates the best power AND powerband. (Not required on all models.)

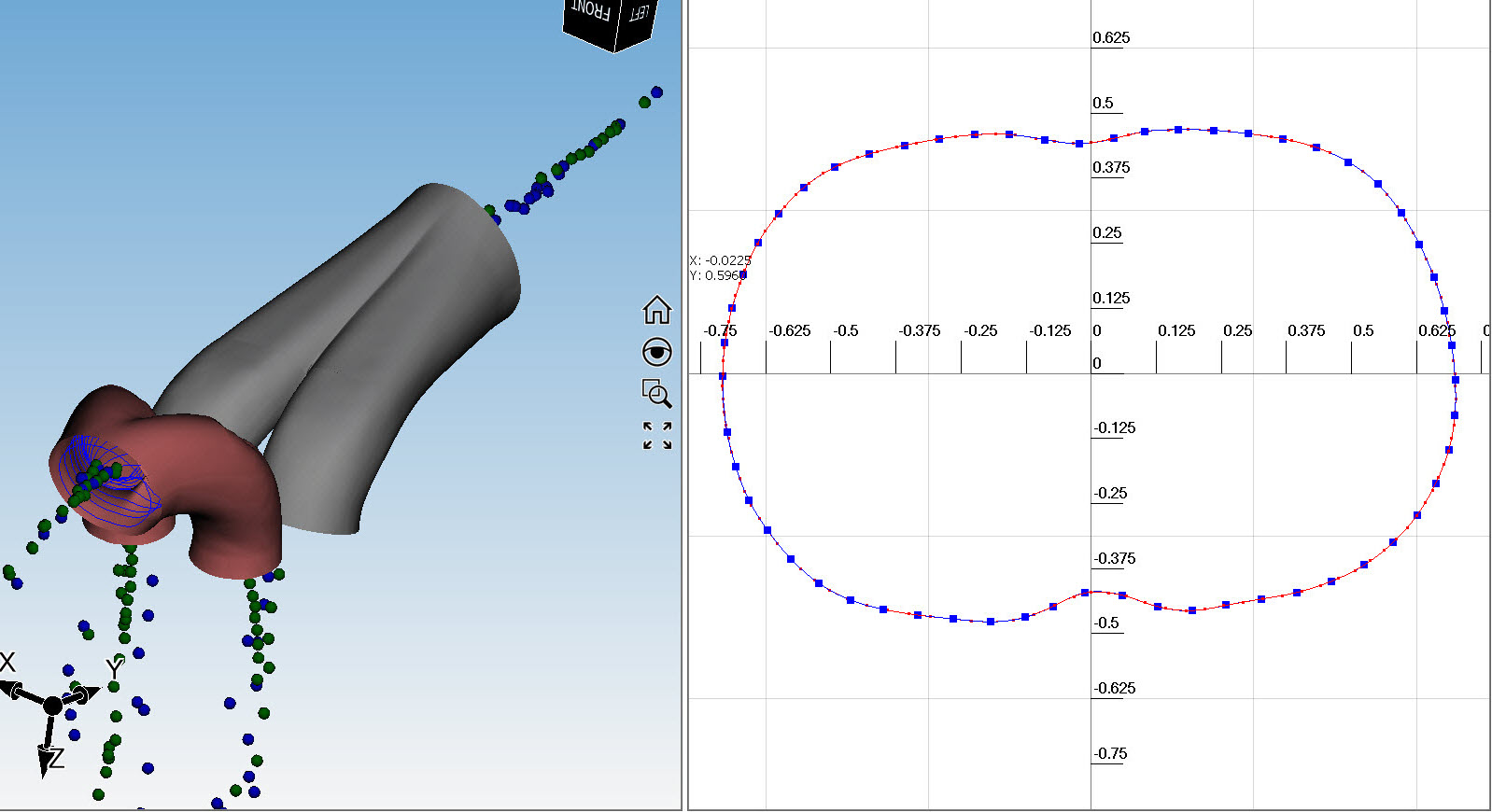

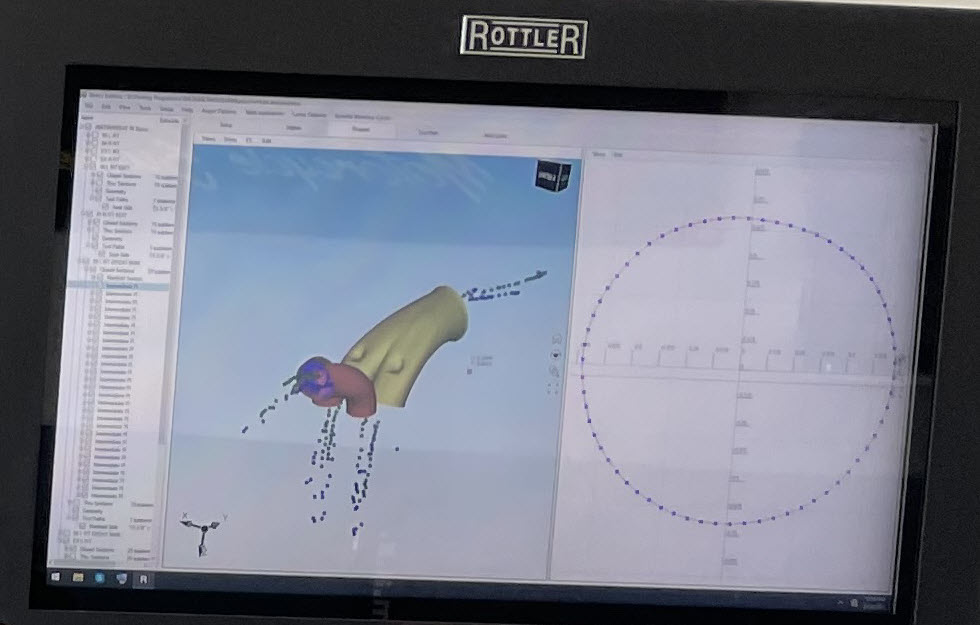

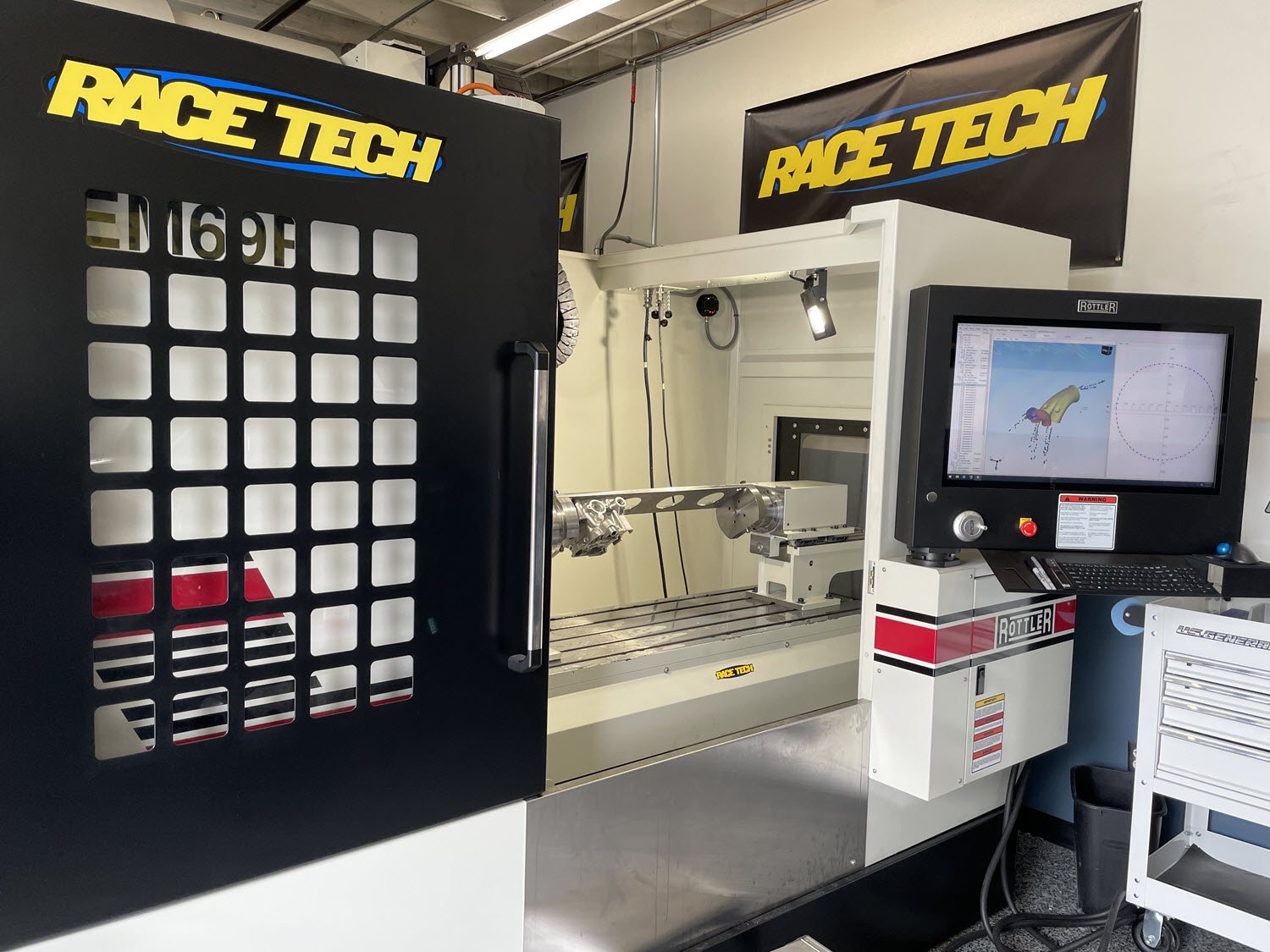

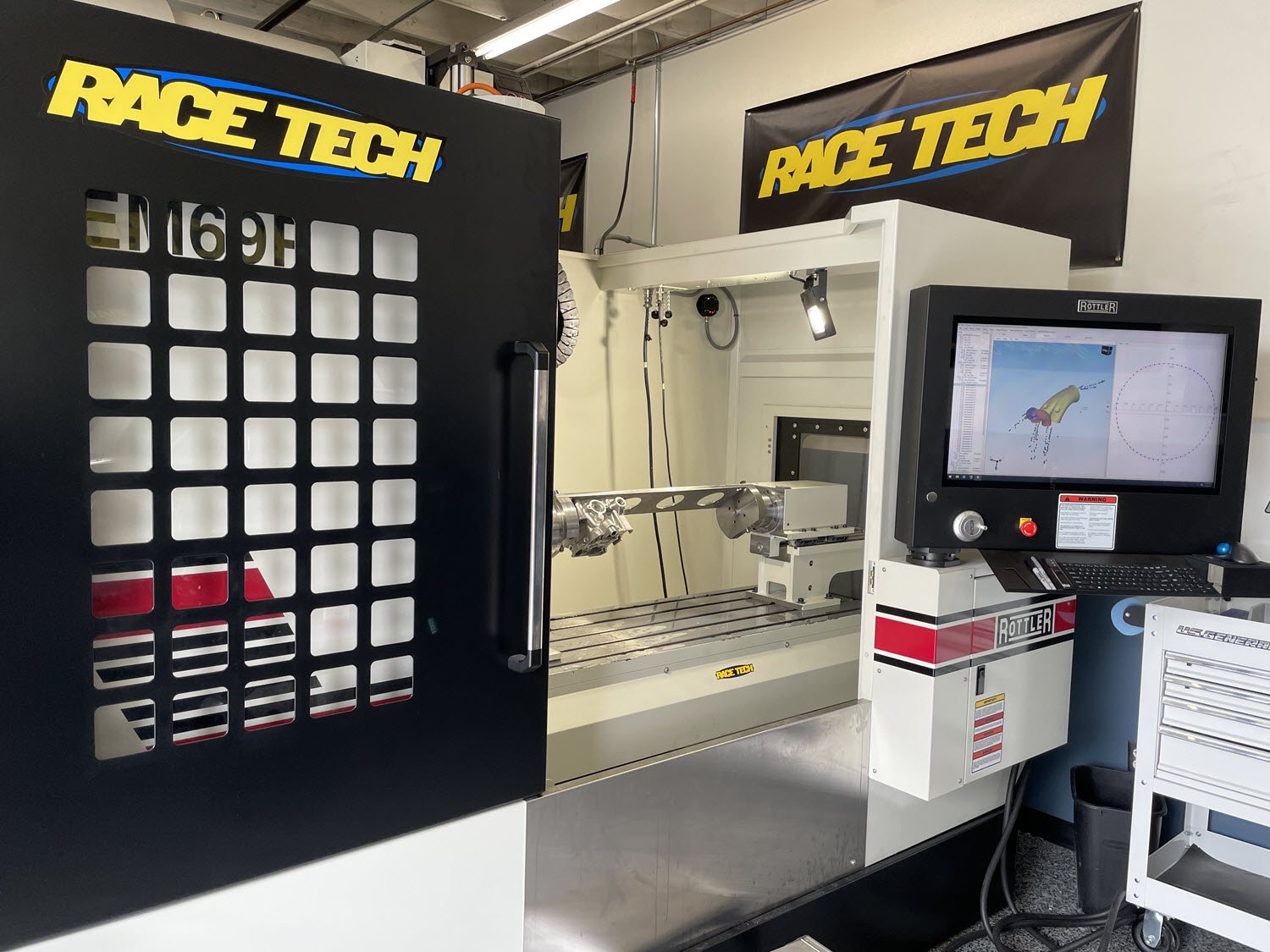

CNC Porting - Rottler EM69P

Engine development requires many hours of trial and error using hand porting techniques, flow bench, dyno, and track analysis. Once a porting design is perfected it is digitized (measured) on the Rottler. This creates a solid model. The solid model is then digitally refined and is ready for precision reproduction.

Race Tech has a Rottler EM69P 5-Axis CNC Porting machine to provide the most accurate, consistent, precision porting available.

CNC Combustion Chamber

The Combustion Chamber can also be optimized and then reproduced with strict adherence to the new design.

4-Stroke Cylinder Head Rebuild

If you send in the complete head assembly with valves and cam installed this service includes disassembly, reassembly and setting valve clearances. When complete you have a ready-to-run head.

Head Decking

Head Decking can be done as a hi-performance upgrade or to repair a damaged head surface. Race Tech machines the surface flat to less than .0005". For hi-performance, head decking is used to tighten squish clearance and raise compression however decking the cylinder is usually preferred.

Valve Job Required

A Valve Job is required when porting a head.

ATTENTION TUNERS - Confidential Port Digitizing and Cutting Available

If you want to develop your own port designs we can digitize and port using the Rottler EM69P. Your port designs are completely private and we provide a Non-Disclosure Agreement. You can take advantage of precise, repeatable, CNC porting without having to buy one.

Head porting is for RACING ONLY! Not for highway (DOT) use.

VALVE and SEAT SERVICES

Valve Jobs - Seats and Guides

A Precision Valve Job is the core of a high-output, reliable motor. Though it may seem strange, Valve Jobs are done on brand new engines. Read on...

Race Tech uses a Rottler SG7 to provide a dependable, accurate, highest quality valve job. The Rottler is proven to be the best in the business for concentricity, surface finish, and valve seat profile.

Concentricity - It is common for stock heads to have .003" to .005" runout. RT Valve Jobs have guaranteed concentricity of less than .001".

Sealing - This outstanding concentricity and surface finish produces a vacuum test of better than 1%. The better it seals the more power it makes.

Durability - This alignment precision reduces valve bounce and side loading. As you might imagine this accuracy reaps huge benefits in the longevity of valves, seats, and guides.

A Certified Spec Sheet is included with every valve job.

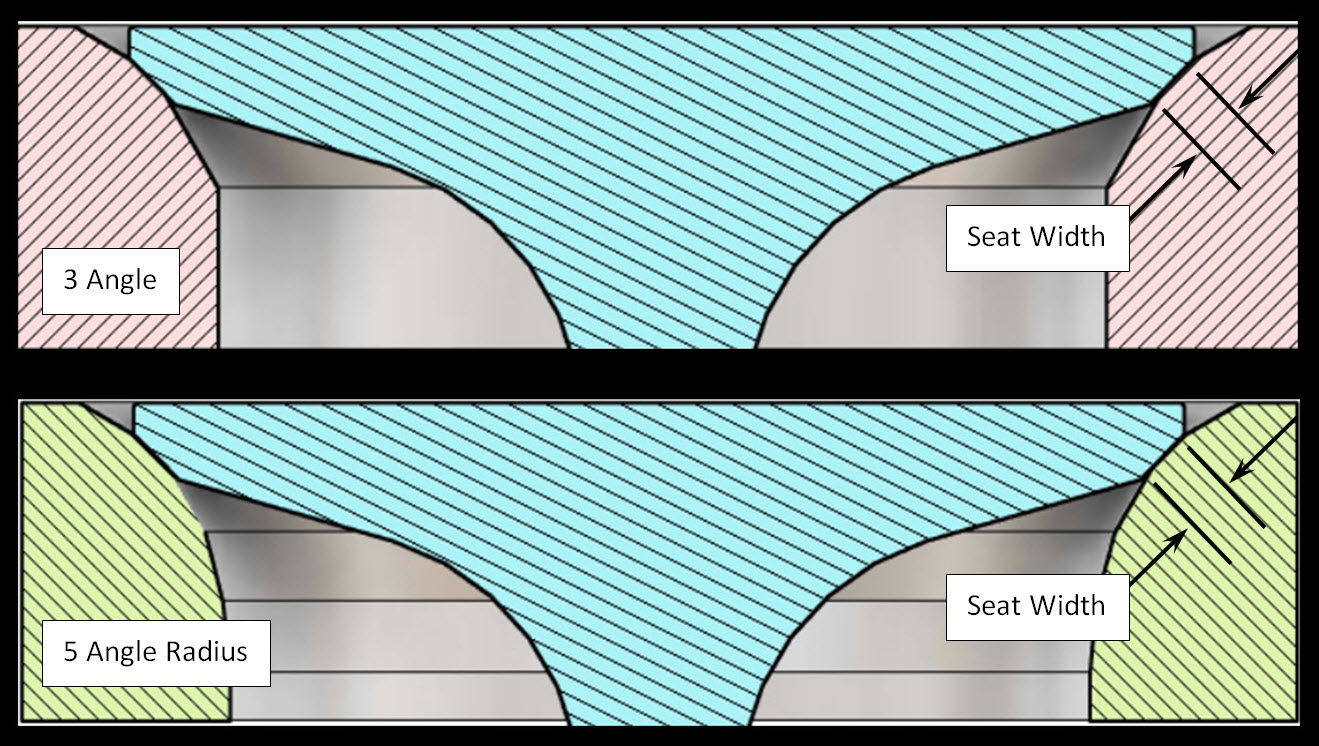

Valve Job Types

- Standard 3-Angle Valve Job

A Standard 3-Angle Valve Job maintains factory designed flow and horsepower.

- Hi-Performance 5-Angle Radius Valve Job

A RT Hi-Performance 5-Angle Radius Valve Job adds horsepower without sacrificing reliability. The area around the valve seat is the most critical area of a port. A 5-Angle Radius Valve Job creates the best flow possible by adding additional angles and a radius. This increases air speed and flow over a 3-Angle Valve Job.

Reliability - The Top Tuners in the world all know a 5-Angle Radius Valve Job has superior flow while providing the same reliability as a 3-Angle Valve Job (the seat width is exactly the same.)

Valve Seats

Race Tech manufactures Valve Seats. We stock many standard sizes and can make custom seats.

We can precisely remove and replace valve seats.

Sometimes even brand new stock seats need to be replaced for one of two reasons. 1) If the stock seat material is poor they are replaced for reliability. 2) Sometimes seats are replaced for better flow characteristics and power.

Valve Guide Installation

Race Tech manufactures Valve Guides. We stock many standard sizes and can make custom guides.

New valve guides are installed and precision honed to the correct tolerance. When guides are replaced, a valve job must be performed to ensure proper valve alignment. These two steps create valve to seat concentricity better than .001".

On certain models brand new stock guides are replaced if there is a known reliability issue.

Valve Guide Honing

When a new valve guide is installed it must be honed to correct tolerance. Honing the valve guide is another often overlooked, yet critical piece of building a World Class engine. If the clearance is too large the valve moves around causing side loading, leakage, and excessive wear.

Valve Refacing and Backcutting

Backcutting for Performance - With our Precision Valve Refacer, we create backcut angles to improve flow. This can be done on Titanium as well as Steel Valves.

Reconditioning Steel Valves - If the stem is within tolerance, a steel valves sealing surface can be reground often for less than the cost of a new valve.

Hi-Performance Titanium Valves

When a stock valve can be improved significantly we design our own. This can increase flow as much as 3 CFM while improving velocity at the same time. Currently KX250 and YZ250F valves are available. Check out the Product Search.

CYLINDER SERVICES

Cylinder Modification and Maintenance

- Cylinder Decking

Deck (4-stroke, single)-

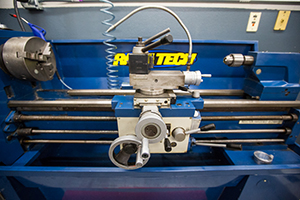

Cylinder Decking is available to repair a damaged cylinder surface or as a hi-performance upgrade. Race Tech uses a lathe with precision expanding mandrels and digital readout to maintain extremely tight tolerances. The surface of the cylinder becomes flat to less than .0005". Machining to raise the compression ratio is also available.

- Cylinder Boring

Cylinder Bore with Rigid Hone (4-stroke, single) -

Race Tech uses a motorcycle specific boring bar to bore 2 or 4 stroke steel sleeved cylinders.

- Big Bores

RT can do sleeving and big bores. We will only do this for applications where it is legal i.e. Vet class and Trail Bikes. No cheaters!

- Sunnen Precision Rigid Hone

Cylinder Hone (4-stroke, single) -

Precision Rigid Honing is a critical yet often overlooked and misunderstood component for producing reliable, repeatable horsepower.

Precision Rigid Honing is an essential process EVERY TIME a piston ring is replaced. This is true for all cylinder materials but is especially true for chrome and Nikasil bores.

Race Tech uses a Sunnen Rigid Hone with special stones to properly surface Nikasil plated bores.

Some models (like YZ250Fs) commonly have bores that are out-of-round by over a half thousandths of an inch. This causes smoking and power loss. RTs Sunnen hone corrects these flaws and produces more horsepower and reliability.

- Please DO NOT use Ball Hones

While ball hones hide cosmetic blemishes they DO NOT remove Ring Rock Grooves. Ring Rock Grooves are areas near the top of the cylinder that have increased wear. This can cause a loss in excess of 1.5 hp on a 250. The correct method is to use a rigid hone with the correct stones.

ENGINE DYNO

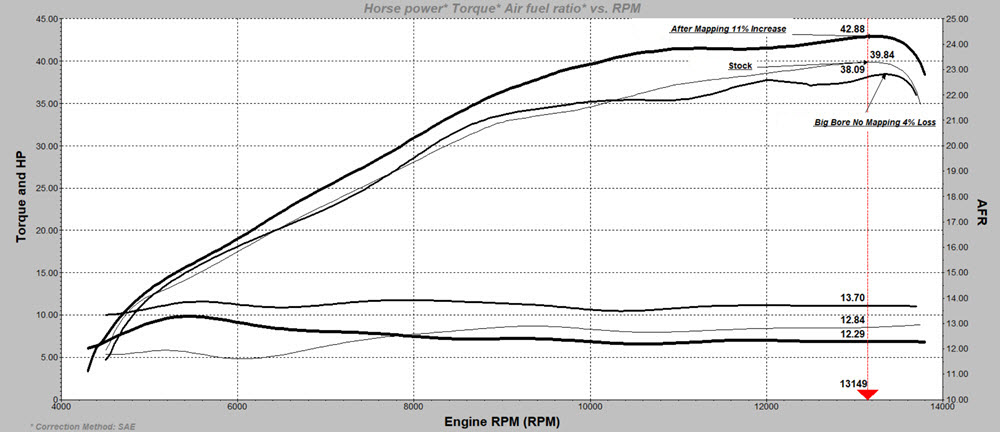

Engine Chassis Dyno

• If you'd like to know how much power your bike really makes, Race Tech offers that service.

• Race Tech uses a high-end Land and Sea chassis dyno equipped with a braking unit and AFR (air fuel ratio) measurement.

• The braking unit provides steady-state dyno testing at all throttle positions and RPMs to produce precise mapping and jetting.

• The Race Tech Dyno can run up to 500 hp and is able to measure motorcycles and UTVs up to 50 inches wide.

• Race Tech has a mobile dyno unit available for trackside tuning and on-site runs at events.

• AFR (Air Fuel Ratio) provides a valuable clue. Part of the dyno run output data is AFR. Though every bike is different, AFR gives RT vital information as to whether an ECU and Mapping will be beneficial.

• Mapping - Race Tech offers Vortex ECU custom maps for the RT Power Plan combination. RT has maps for both race fuel and pump gas for most current popular dirt bikes.

• Custom Mapping - RT can develop Custom Maps for your unique combination of components.

• CONFIDENTIALITY - We will dyno your bike and provide data sheets with complete confidentiality.

FLOW BENCH

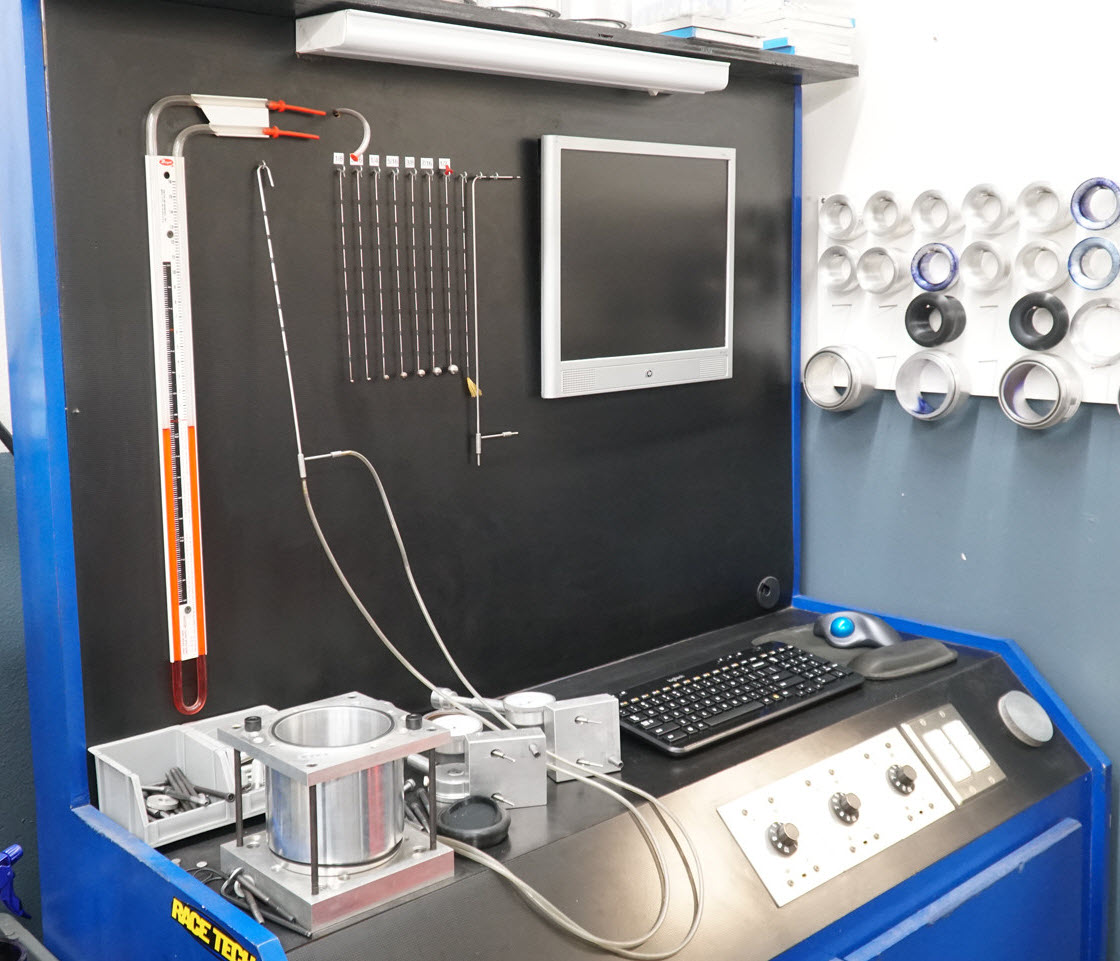

Custom Flow Bench

A Flow Bench is used to measure maximum flow as well as air velocity. Increasing air flow can be as easy as enlarging ports. This typically increases maximum horsepower but often decreases air velocity. Decreased velocity robs low and midrange power AND throttle response. Many "high-performance engines" are built this way.

The real trick is to increase air flow AND air velocity. This is very difficult to do if the tuner doesn't invest the time on the Flow Bench. This essential step is commonly skipped even by tuners that own a Flow Bench.

Race Tech has a custom built, computerized, state-of-the-art Flow Bench capable of flowing 28 inches at 600 CFM (yeah... those are big numbers - don't stand too close). It is an essential part of the R&D process developing the RT Power Plan.

Velocity is critical! Utilizing a pitot tube and Port Flow Analyzer Pro Software with fully digital air flow measurement, RT creates and analyzes port velocity maps and flow graphs.

Wet Flow Analysis - This gives us key visual insights on what the air and fuel actually do.

Confidentiality - Tuners - we can flow test your head and provide you data sheets with complete confidentiality.

SODA BLASTING and ULTRASONIC CLEANING

Cleanliness is Critical

Race Tech has invested in hi-quality cleaning methods that are safe and effective.

- Soda Blasting

Race Tech uses an ABS Products Soda Blaster to produce a like-new finish to decarbon and clean engine components. We use a Soda Blaster instead of a bead blaster because it prevents the possibility of leaving abrasive material (glass/sand/egg shells) behind that can damage an engine. The Soda Blaster cleans using non-abrasive baking soda at extremely high pressures.

- Ultrasonic Cleaner

The Pro Ultrasonic uses high frequency waves with a special cleaning solution specifically for engines to provide a spotless finish.

The little things count!

CRANK REBUILDING

Crank Rebuilding

The Crank Assembly is the heart of the engine. It must be reliable and run true. Many cranks are out-of-true from the factory.

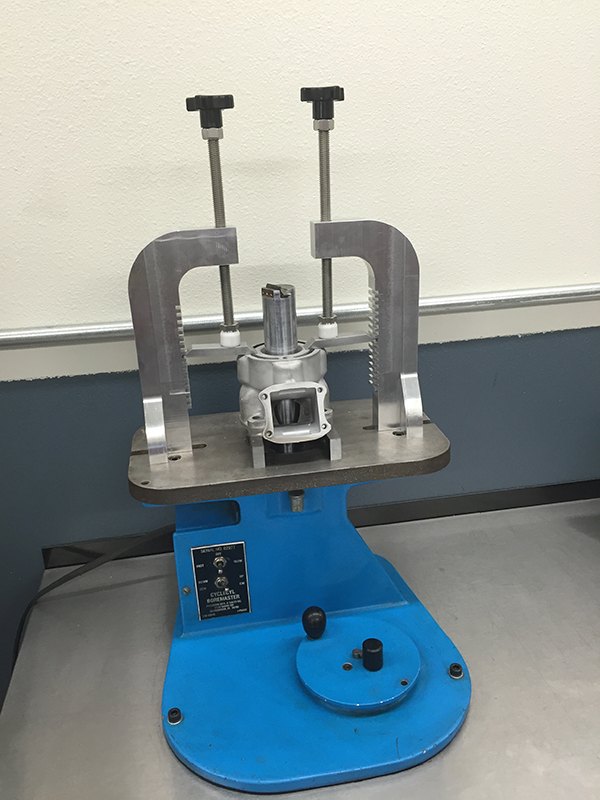

Using a special assembly jig Race Tech replaces the connecting rod, pin, and bearing. The final precision truing is held to a run-out of less than .001".

Rebuilding Service includes a spec sheet.

VORTEX IGNITIONS

and RT CUSTOM MAPPING

Vortex ECUs

An Engine Control Unit (ECU) provides the engine with fuel and ignition timing. A good ECU and Map can produce an impressive improvement in performance.

Race Tech offers Vortex ECUs and Custom Mapping Services.

We stock Vortex Ignitions for many models. They come with a standard base map installed.

Mapping

RT has developed maps that outperform the standard base map.

RT Power Plans require mapping to maximize performance. These have been developed for popular race fuels as well as pump gas.

RT has developed maps for many other modified component packages other than the RT Power Plan.

Race Tech can develop a custom map for your specific engine package too.

Vortex ECUs are for RACING ONLY! Not for highway (DOT) use.

CP PISTONS

CP Pistons

Pistons are critical for both reliability and horsepower! Testing aftermarket pistons have shown wide fluctuations in both these areas.

After years of experience and testing, CP has become the trusted piston supplier for Race Tech Engine Services. CP Pistons have proven to make the best power and are very durable.

KTM Factory relies on CP for their race engines.

Race Tech keeps many models in stock.

FMF EXHAUST PIPES

FMF Exhausts

There are a lot of choices out there and some are very good. Race Tech has done a lot of research and recommends FMF Pipes. FMF has consistently produced improved performance with every pipe we have tested.

FMF Pipes can be obtained directly through Race Tech.

RT ENGINE TOOLS

RT Engine Tools

Wherever we see a need for an outstanding tool we search to recommend the best available. When we can produce a tool that is even better we do. So far...

- RT Valve Spring Compressor

If you build a significant quantity of 4-strokes you are going to love this tool! RT has created a Valve Spring Compressor that makes disassembly and assembly of heads quick and easy. It is foot-operated and has a slide hammer built in for stubborn keepers. Includes 3 size drivers for small to large motorcycle and automotive engines. You will love it!

TESC 01 -

CUSTOMER SERVICE - ENGINES

At Race Tech here are your options:

- Send your Engine Components in for Hi-Performance Machining

- Have your Motorcycle Dyno Tuned & Fuel Mapped

- Call Race Tech to order components or with questions: 951.279.6655 option 4 or ext 116

- Many Race Tech Centers can do high quality engine assembly. (We do not build complete engines at RT)

Our customers' satisfaction is vital. We put it in writing. ►Policies

RACE TECH ENGINE SERVICE CENTERS

Race Tech Engine Service Centers

Race Tech specializes in providing precision engine machining and R&D services but we do not build complete engines.

If you're looking for a trusted source to build your engine, the following Race Tech Engine Service Centers exclusively use RT for their machining services.

Crow Performance - California - crowperformance@gmail.com - 760.295.3303

RJH Suspension & Engine - Arkansas - ray@johnshonda.com - 501.385.2178

Syndicate Development - Idaho - haskettd@live.com - 208.251.9536

RACE TECH POWER PLAN™

Race Tech Power Plan™

Developing the best combination of porting, cam timing, mapping, and related components to build "World Class" engines is a painstaking process. Race Tech has spent an impressive number of hours doing R&D on the Flow Bench, Dyno, Rottler EM69P CNC, and at the Track.

The Race Tech Power Plan™ is a list of components that, when assembled, will produce impressive power, powerband AND reliability. If you follow the RT Power Plan™ and assemble the engine correctly you can build an engine capable of competing with anything in the world.

Includes recommendations for:

4-Stroke Engines

- Head Porting Type>Full Porting with possible addition of Epoxy to improve bottom-end power and throttle response

- Valve Job Type>5-Angle Radius Valve Job

- Cam and/or Cam Timing Changes

- Piston Manufacturer and Compression Ratio

- Valves or Valve Mod

- Valve Seats (for performance and/or reliability)

- Valve Guides (if there is an issue with stock)

- Valve Springs

- ECU and RT Mapping (for Race Gas and Pump Gas)

- Exhaust Pipe

- Also listed are model specific concerns

- If not included in the RT Power Plan, stock is recommended

2-Stroke Engines

- Porting

- Head Mod

- Piston

- Exhaust Pipe

Additional Care - many engines have reported areas of concern for reliability. For example some engines have weak timing chains. Known items are listed in the Additional Care line of the Engine Product Search.

To view the Race Tech Power Plan do an Engine Search

Engine modifications are for RACING ONLY! Not for highway (DOT) use.

CNC HEAD PORTING

Head Porting - 4 Stroke Engines

Engine modification is for RACING ONLY! Not for highway (DOT) use.

3 Types of Porting

Race Tech's head porting provides an increase in flow and velocity to gain both powerband and peak horsepower. Race Tech porting is developed using a combination of flow bench, dyno and track testing data.

A Valve Job is required with porting.

1. Race Tech Pocket Porting

Race Tech's innovative Pocket Porting provides 75% of the flow and velocity gains available while maintaining a great price point. If you look at the two graphics at the left what it is showing is the importance of the four sections of the port. Notice that 40% of the gains possible are very close to the valve seat opening. A whopping 75% of the total potential is covered only slightly further down the port (40% plus 35%). By focusing on these areas we can provide the best bang-for-the-buck.

2. Hi-Performance Full Porting

Full Porting increases flow and velocity for maximum efficiency (from flow bench data). This option is available when cost is no object and you are looking for the best available. The entire port is addressed.

In some cases extensive modification of the combustion chamber is required.

3. Hi-Performance Full Porting - with EPOXY

Certain models benefit greatly by making the intake port runners smaller. When the ports are too large the air velocity slows down and low-end, mid-range and throttle response are negatively affected.

Adding epoxy to make the port smaller increases velocity. On these models low and mid-range power are improved while actually increasing top-end. On models where this is offered, this modification creates the best power AND powerband. (Not required on all models.)

CNC Porting - Rottler EM69P

Engine development requires many hours of trial and error using hand porting techniques, flow bench, dyno, and track analysis. Once a porting design is perfected it is digitized (measured) on the Rottler. This creates a solid model. The solid model is then digitally refined and is ready for precision reproduction.

Race Tech has a Rottler EM69P 5-Axis CNC Porting machine to provide the most accurate, consistent, precision porting available.

CNC Combustion Chamber

The Combustion Chamber can also be optimized and then reproduced with strict adherence to the new design.

4-Stroke Cylinder Head Rebuild

If you send in the complete head assembly with valves and cam installed this service includes disassembly, reassembly and setting valve clearances. When complete you have a ready-to-run head.

Head Decking

Head Decking can be done as a hi-performance upgrade or to repair a damaged head surface. Race Tech machines the surface flat to less than .0005". For hi-performance, head decking is used to tighten squish clearance and raise compression however decking the cylinder is usually preferred.

Valve Job Required

A Valve Job is required when porting a head.

ATTENTION TUNERS - Confidential Port Digitizing and Cutting Available

If you want to develop your own port designs we can digitize and port using the Rottler EM69P. Your port designs are completely private and we provide a Non-Disclosure Agreement. You can take advantage of precise, repeatable, CNC porting without having to buy one.

Head porting is for RACING ONLY! Not for highway (DOT) use.

VALVE and SEAT SERVICES

Valve Jobs - Seats and Guides

A Precision Valve Job is the core of a high-output, reliable motor. Though it may seem strange, Valve Jobs are done on brand new engines. Read on...

Race Tech uses a Rottler SG7 to provide a dependable, accurate, highest quality valve job. The Rottler is proven to be the best in the business for concentricity, surface finish, and valve seat profile.

Concentricity - It is common for stock heads to have .003" to .005" runout. RT Valve Jobs have guaranteed concentricity of less than .001".

Sealing - This outstanding concentricity and surface finish produces a vacuum test of better than 1%. The better it seals the more power it makes.

Durability - This alignment precision reduces valve bounce and side loading. As you might imagine this accuracy reaps huge benefits in the longevity of valves, seats, and guides.

A Certified Spec Sheet is included with every valve job.

Valve Job Types

- Standard 3-Angle Valve Job

A Standard 3-Angle Valve Job maintains factory designed flow and horsepower.

- Hi-Performance 5-Angle Radius Valve Job

A RT Hi-Performance 5-Angle Radius Valve Job adds horsepower without sacrificing reliability. The area around the valve seat is the most critical area of a port. A 5-Angle Radius Valve Job creates the best flow possible by adding additional angles and a radius. This increases air speed and flow over a 3-Angle Valve Job.

Reliability - The Top Tuners in the world all know a 5-Angle Radius Valve Job has superior flow while providing the same reliability as a 3-Angle Valve Job (the seat width is exactly the same.)

Valve Seats

Race Tech manufactures Valve Seats. We stock many standard sizes and can make custom seats.

We can precisely remove and replace valve seats.

Sometimes even brand new stock seats need to be replaced for one of two reasons. 1) If the stock seat material is poor they are replaced for reliability. 2) Sometimes seats are replaced for better flow characteristics and power.

Valve Guide Installation

Race Tech manufactures Valve Guides. We stock many standard sizes and can make custom guides.

New valve guides are installed and precision honed to the correct tolerance. When guides are replaced, a valve job must be performed to ensure proper valve alignment. These two steps create valve to seat concentricity better than .001".

On certain models brand new stock guides are replaced if there is a known reliability issue.

Valve Guide Honing

When a new valve guide is installed it must be honed to correct tolerance. Honing the valve guide is another often overlooked, yet critical piece of building a World Class engine. If the clearance is too large the valve moves around causing side loading, leakage, and excessive wear.

Valve Refacing and Backcutting

Backcutting for Performance - With our Precision Valve Refacer, we create backcut angles to improve flow. This can be done on Titanium as well as Steel Valves.

Reconditioning Steel Valves - If the stem is within tolerance, a steel valves sealing surface can be reground often for less than the cost of a new valve.

Hi-Performance Titanium Valves

When a stock valve can be improved significantly we design our own. This can increase flow as much as 3 CFM while improving velocity at the same time. Currently KX250 and YZ250F valves are available. Check out the Product Search.

CYLINDER SERVICES

Cylinder Modification and Maintenance

- Cylinder Decking

Deck (4-stroke, single)-

Cylinder Decking is available to repair a damaged cylinder surface or as a hi-performance upgrade. Race Tech uses a lathe with precision expanding mandrels and digital readout to maintain extremely tight tolerances. The surface of the cylinder becomes flat to less than .0005". Machining to raise the compression ratio is also available.

- Cylinder Boring

Cylinder Bore with Rigid Hone (4-stroke, single) -

Race Tech uses a motorcycle specific boring bar to bore 2 or 4 stroke steel sleeved cylinders.

- Big Bores

RT can do sleeving and big bores. We will only do this for applications where it is legal i.e. Vet class and Trail Bikes. No cheaters!

- Sunnen Precision Rigid Hone

Cylinder Hone (4-stroke, single) -

Precision Rigid Honing is a critical yet often overlooked and misunderstood component for producing reliable, repeatable horsepower.

Precision Rigid Honing is an essential process EVERY TIME a piston ring is replaced. This is true for all cylinder materials but is especially true for chrome and Nikasil bores.

Race Tech uses a Sunnen Rigid Hone with special stones to properly surface Nikasil plated bores.

Some models (like YZ250Fs) commonly have bores that are out-of-round by over a half thousandths of an inch. This causes smoking and power loss. RTs Sunnen hone corrects these flaws and produces more horsepower and reliability.

- Please DO NOT use Ball Hones

While ball hones hide cosmetic blemishes they DO NOT remove Ring Rock Grooves. Ring Rock Grooves are areas near the top of the cylinder that have increased wear. This can cause a loss in excess of 1.5 hp on a 250. The correct method is to use a rigid hone with the correct stones.

ENGINE DYNO

Engine Chassis Dyno

• If you'd like to know how much power your bike really makes, Race Tech offers that service.

• Race Tech uses a high-end Land and Sea chassis dyno equipped with a braking unit and AFR (air fuel ratio) measurement.

• The braking unit provides steady-state dyno testing at all throttle positions and RPMs to produce precise mapping and jetting.

• The Race Tech Dyno can run up to 500 hp and is able to measure motorcycles and UTVs up to 50 inches wide.

• Race Tech has a mobile dyno unit available for trackside tuning and on-site runs at events.

• AFR (Air Fuel Ratio) provides a valuable clue. Part of the dyno run output data is AFR. Though every bike is different, AFR gives RT vital information as to whether an ECU and Mapping will be beneficial.

• Mapping - Race Tech offers Vortex ECU custom maps for the RT Power Plan combination. RT has maps for both race fuel and pump gas for most current popular dirt bikes.

• Custom Mapping - RT can develop Custom Maps for your unique combination of components.

• CONFIDENTIALITY - We will dyno your bike and provide data sheets with complete confidentiality.

FLOW BENCH

Custom Flow Bench

A Flow Bench is used to measure maximum flow as well as air velocity. Increasing air flow can be as easy as enlarging ports. This typically increases maximum horsepower but often decreases air velocity. Decreased velocity robs low and midrange power AND throttle response. Many "high-performance engines" are built this way.

The real trick is to increase air flow AND air velocity. This is very difficult to do if the tuner doesn't invest the time on the Flow Bench. This essential step is commonly skipped even by tuners that own a Flow Bench.

Race Tech has a custom built, computerized, state-of-the-art Flow Bench capable of flowing 28 inches at 600 CFM (yeah... those are big numbers - don't stand too close). It is an essential part of the R&D process developing the RT Power Plan.

Velocity is critical! Utilizing a pitot tube and Port Flow Analyzer Pro Software with fully digital air flow measurement, RT creates and analyzes port velocity maps and flow graphs.

Wet Flow Analysis - This gives us key visual insights on what the air and fuel actually do.

Confidentiality - Tuners - we can flow test your head and provide you data sheets with complete confidentiality.

SODA BLASTING and ULTRASONIC CLEANING

Cleanliness is Critical

Race Tech has invested in hi-quality cleaning methods that are safe and effective.

- Soda Blasting

Race Tech uses an ABS Products Soda Blaster to produce a like-new finish to decarbon and clean engine components. We use a Soda Blaster instead of a bead blaster because it prevents the possibility of leaving abrasive material (glass/sand/egg shells) behind that can damage an engine. The Soda Blaster cleans using non-abrasive baking soda at extremely high pressures.

- Ultrasonic Cleaner

The Pro Ultrasonic uses high frequency waves with a special cleaning solution specifically for engines to provide a spotless finish.

The little things count!

CRANK REBUILDING

Crank Rebuilding

The Crank Assembly is the heart of the engine. It must be reliable and run true. Many cranks are out-of-true from the factory.

Using a special assembly jig Race Tech replaces the connecting rod, pin, and bearing. The final precision truing is held to a run-out of less than .001".

Rebuilding Service includes a spec sheet.

VORTEX IGNITIONS

and RT CUSTOM MAPPING

Vortex ECUs

An Engine Control Unit (ECU) provides the engine with fuel and ignition timing. A good ECU and Map can produce an impressive improvement in performance.

Race Tech offers Vortex ECUs and Custom Mapping Services.

We stock Vortex Ignitions for many models. They come with a standard base map installed.

Mapping

RT has developed maps that outperform the standard base map.

RT Power Plans require mapping to maximize performance. These have been developed for popular race fuels as well as pump gas.

RT has developed maps for many other modified component packages other than the RT Power Plan.

Race Tech can develop a custom map for your specific engine package too.

Vortex ECUs are for RACING ONLY! Not for highway (DOT) use.

CP PISTONS

CP Pistons

Pistons are critical for both reliability and horsepower! Testing aftermarket pistons have shown wide fluctuations in both these areas.

After years of experience and testing, CP has become the trusted piston supplier for Race Tech Engine Services. CP Pistons have proven to make the best power and are very durable.

KTM Factory relies on CP for their race engines.

Race Tech keeps many models in stock.

FMF EXHAUST PIPES

FMF Exhausts

There are a lot of choices out there and some are very good. Race Tech has done a lot of research and recommends FMF Pipes. FMF has consistently produced improved performance with every pipe we have tested.

FMF Pipes can be obtained directly through Race Tech.

RT ENGINE TOOLS

RT Engine Tools

Wherever we see a need for an outstanding tool we search to recommend the best available. When we can produce a tool that is even better we do. So far...

- RT Valve Spring Compressor

If you build a significant quantity of 4-strokes you are going to love this tool! RT has created a Valve Spring Compressor that makes disassembly and assembly of heads quick and easy. It is foot-operated and has a slide hammer built in for stubborn keepers. Includes 3 size drivers for small to large motorcycle and automotive engines. You will love it!

TESC 01 -

CUSTOMER SERVICE - ENGINES

At Race Tech here are your options:

- Send your Engine Components in for Hi-Performance Machining

- Have your Motorcycle Dyno Tuned & Fuel Mapped

- Call Race Tech to order components or with questions: 951.279.6655 option 4 or ext 116

- Many Race Tech Centers can do high quality engine assembly. (We do not build complete engines at RT)

Our customers' satisfaction is vital. We put it in writing. ►Policies

RACE TECH ENGINE SERVICE CENTERS

Race Tech Engine Service Centers

Race Tech specializes in providing precision engine machining and R&D services but we do not build complete engines.

If you're looking for a trusted source to build your engine, the following Race Tech Engine Service Centers exclusively use RT for their machining services.

Crow Performance - California - crowperformance@gmail.com - 760.295.3303

RJH Suspension & Engine - Arkansas - ray@johnshonda.com - 501.385.2178

Syndicate Development - Idaho - haskettd@live.com - 208.251.9536