Nitrogen Charging Bolt Installation - SPNV 0512 | |

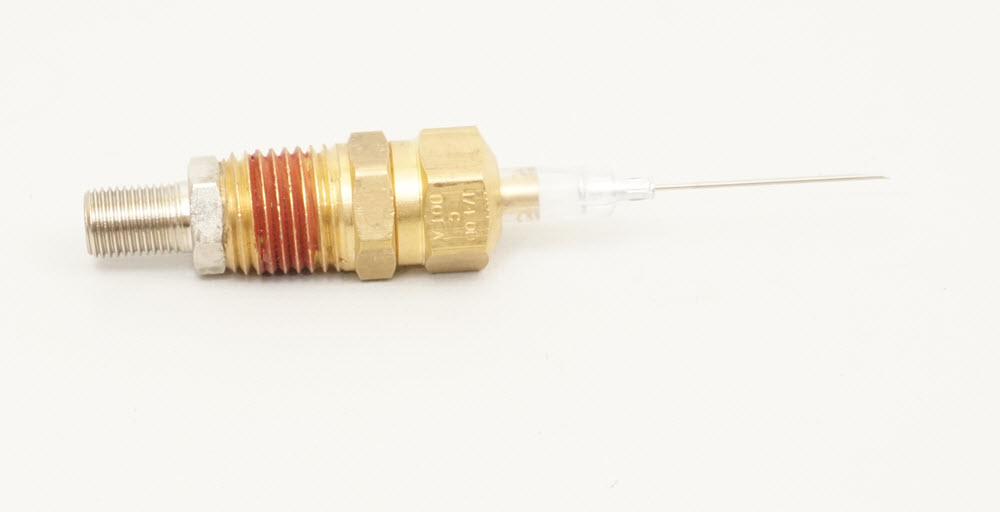

Supplies Needed SPNV 0512 - Nitrogen Charging Bolt - Add to Cart TSSN 01 - Nitrogen Charging Needle - Add to Cart M5x.8 Tap 4.2mm Drill Flat file or mill

| |

Step 1 - Mount the shock in a vise with the body eyelet at its highest point. Make a small punch mark to guide the drill bit on initial entry. Release the nitrogen pressure by drilling an 1/8" (3mm) hole perpendicular to the surface. Note: In some shocks the reservoir piston or bladder cannot be removed even after the shock is disassembled. In this case the metal chips must be thoroughly removed. Dab a small amount of grease on the end of the drill bit to help catch metal filings. IMPORTANT! Eye protection is required to protect against small projectiles when the pressure is released. And lastly keep your mouth closed. |  |

Step 2 - After pressure is released, disassemble the shock by removing the seal head and shaft assembly. Discard oil in an appropriate container and rinse the shock body to clean the surface of any contaminants. Mount the shock body back in the vise to proceed. Note: On shocks with captive bladders or pistons the reservoir volume must be cleaned completely. It can be helpful to use an air nozzle with a long tube on it. Insert the tube into the hole and blow out the chamber from the inside out. |  |

Step 3 - Increase the hole size to 4.2mm (#19) which is the proper diameter for an M5 x 0.8 tap. Note: Make sure the drill bit is perpendicular to the surface. |  |

Step 4 - Make a flat where the bolt head must seal by milling or carefully filing. |  |

Step 5 - Tap the hole to M5 x 0.8mm Note: Use tapping fluid. Make sure tap is perpendicular to the surface. Clean all shavings and debris inside and out. |  |

Step 6 - Put the o-ring and washer on the SPNV 0512 and install on the shock. Use thread lock. |  |

Shock Assembly - There are 3 basic shock styles:

| |