3.1 Betor & Bultaco 35 & 38mm |

||

|

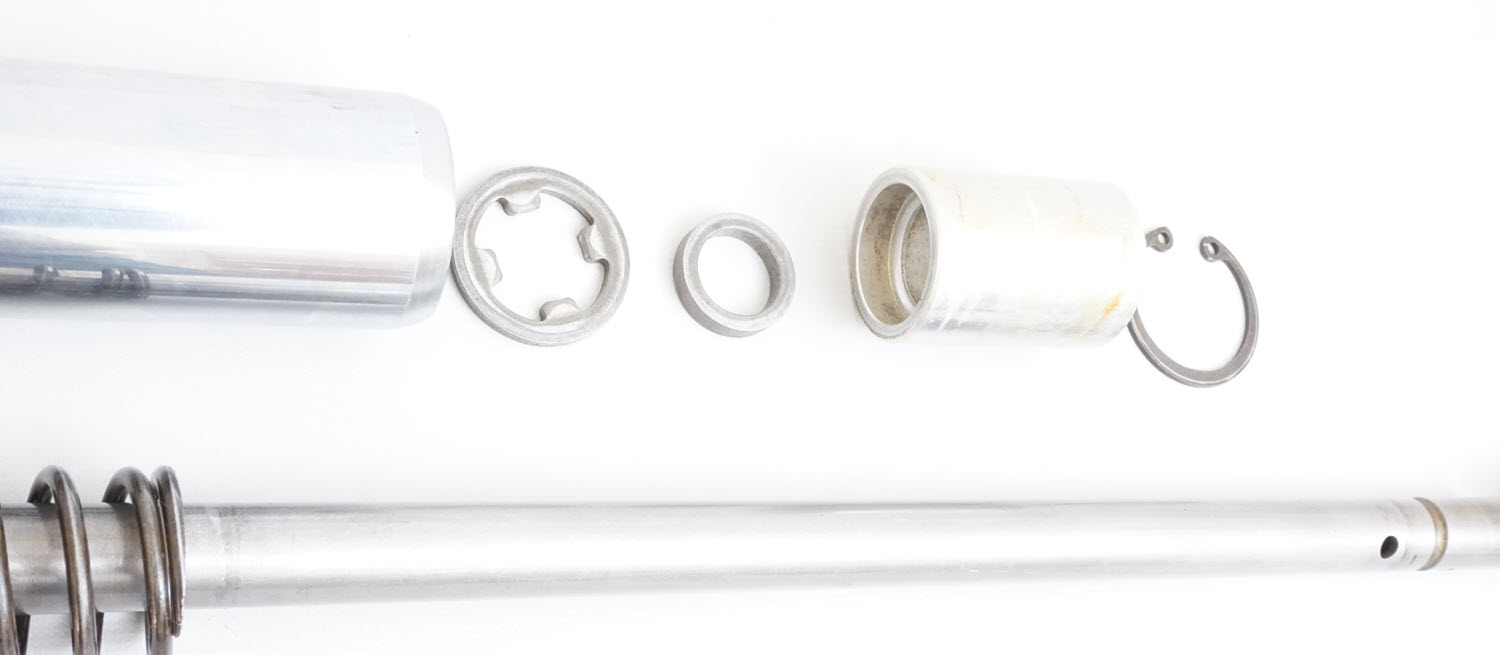

Betor and Bultaco Damping Rods have the bottoming cone pressed onto the rod. The best way to remove the rod from the fork is to remove the circlip and check valve from the bottom of the chrome tube.

38mm |

|

|

Enlarge the Compression Feed Drill the compression holes to a quantity of 6 holes of 6mm (1/4"). Make sure to protect the check valve components during this process. Clean any metal shavings from the check valve prior to re-installing the rod assembly into the fork tube. Modified rod on the left, stock rod on the right. If you must remove the bottoming cone for any reason it must be pressed off the rod. It may also have a roll pin, remove the roll pin if applicable (remember to reinstall too.) Use a heat gun to warm up the cone. Thread the bottom bolt part way into the rod. Remove the cone by tapping on the bolt. |

|

|

Adapters

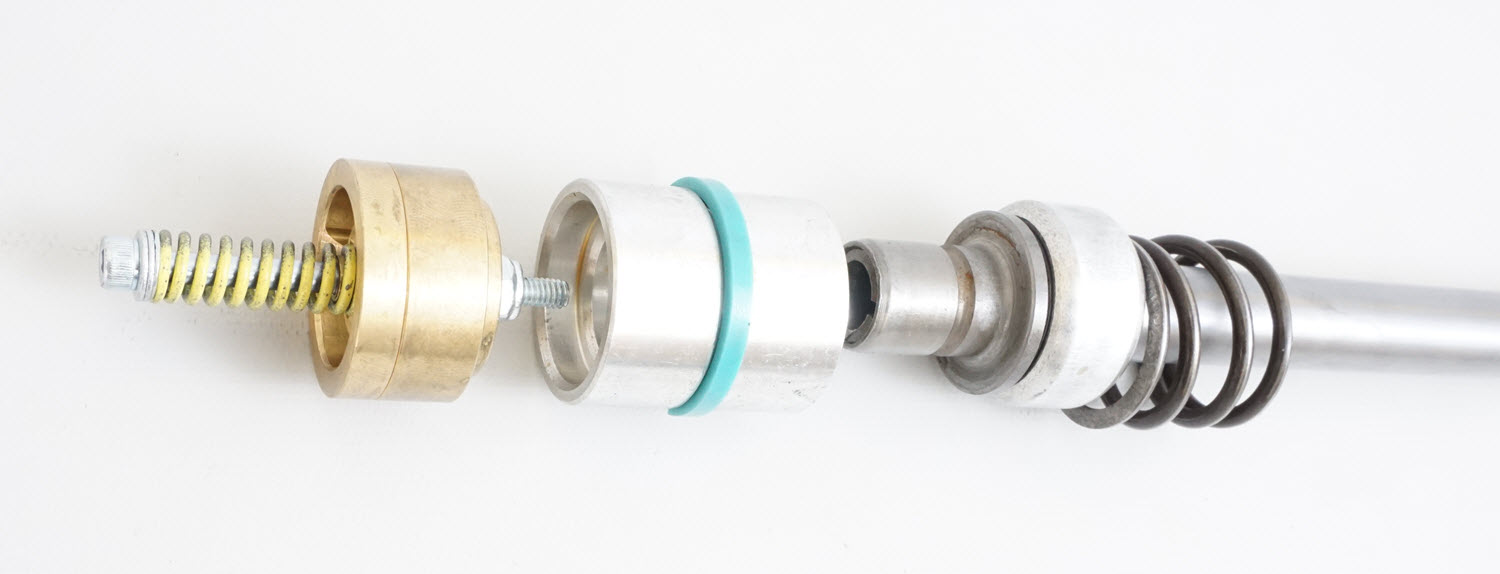

Emulator Adapters with piston rings are included with the kits. The adapter fits over the spring post on top of the rod. No modifications to top of rod are required. |

|

|

Sealing

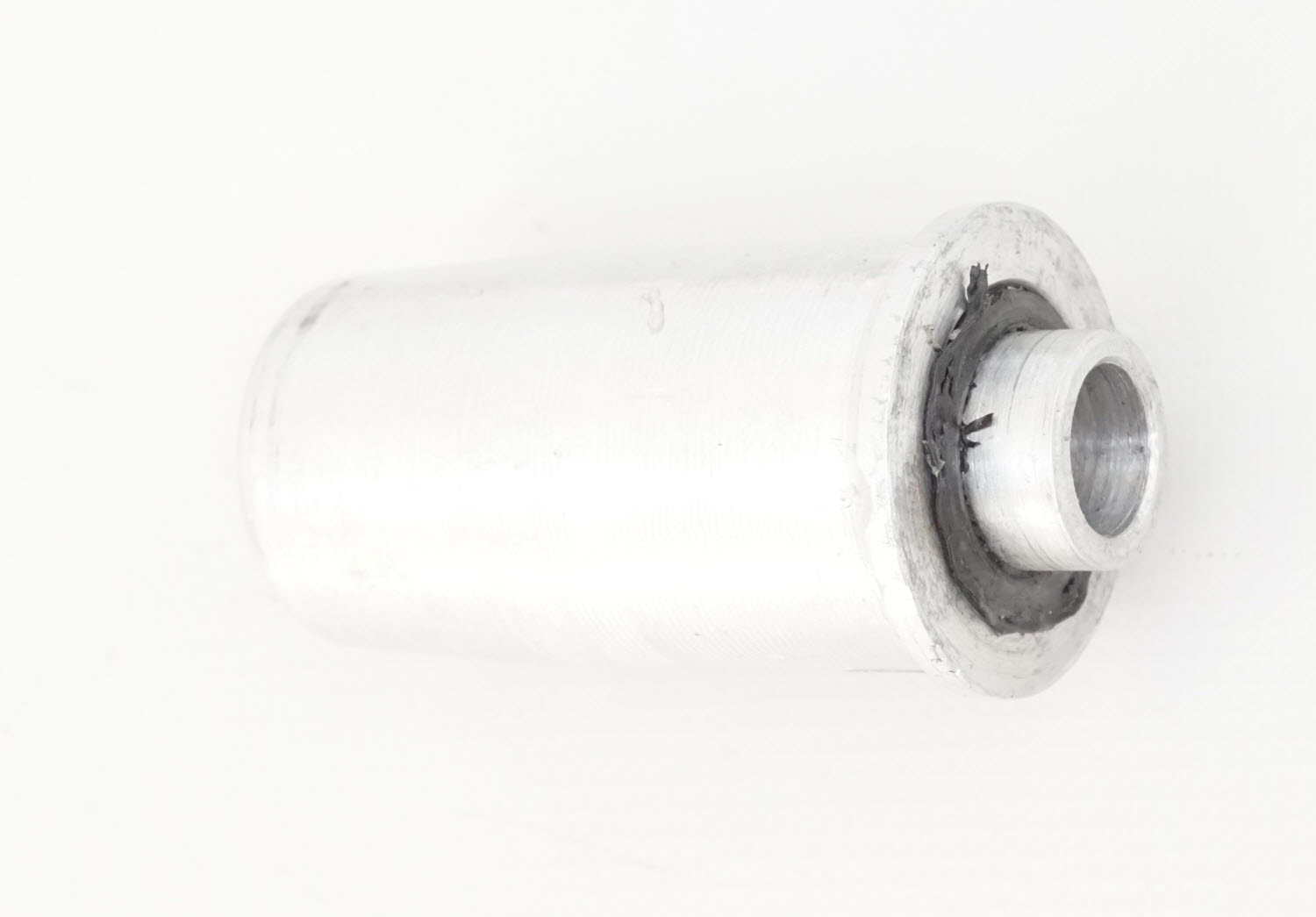

Stock there is a rubber flat washer that seals the rod to the cone (inside the bottoming cone on the other side.) There is also a rubber washer in a groove on the bottom of the cone (shown). This is a really silly design. It is far better to remove all that and use copper sealing washers (HMWC 0813) on the bolt on the outside of the fork leg. No other washers or lock washers are required. |

|

|

Check Valve If you do take the Check Valve out of the bottom of the fork leg this is a picture of the order and orientation of the hardware. |

|

|

Ready for Assembly Top - stock Bottom - modified

Fork Caps Betor and Bultaco Fork Caps with Air Vents should be sealed up using Epoxy, Liquid Metal, etc. Vents may be small holes at cap outside hex or above O-Ring and at inside bottom center of cap. Some Caps have Screw at the top: Remove Screw, spring, Check ball and fill with epoxy , reinstall screw

See Standard Emulator Instructions for spring preload and oil level guidance.

|

|