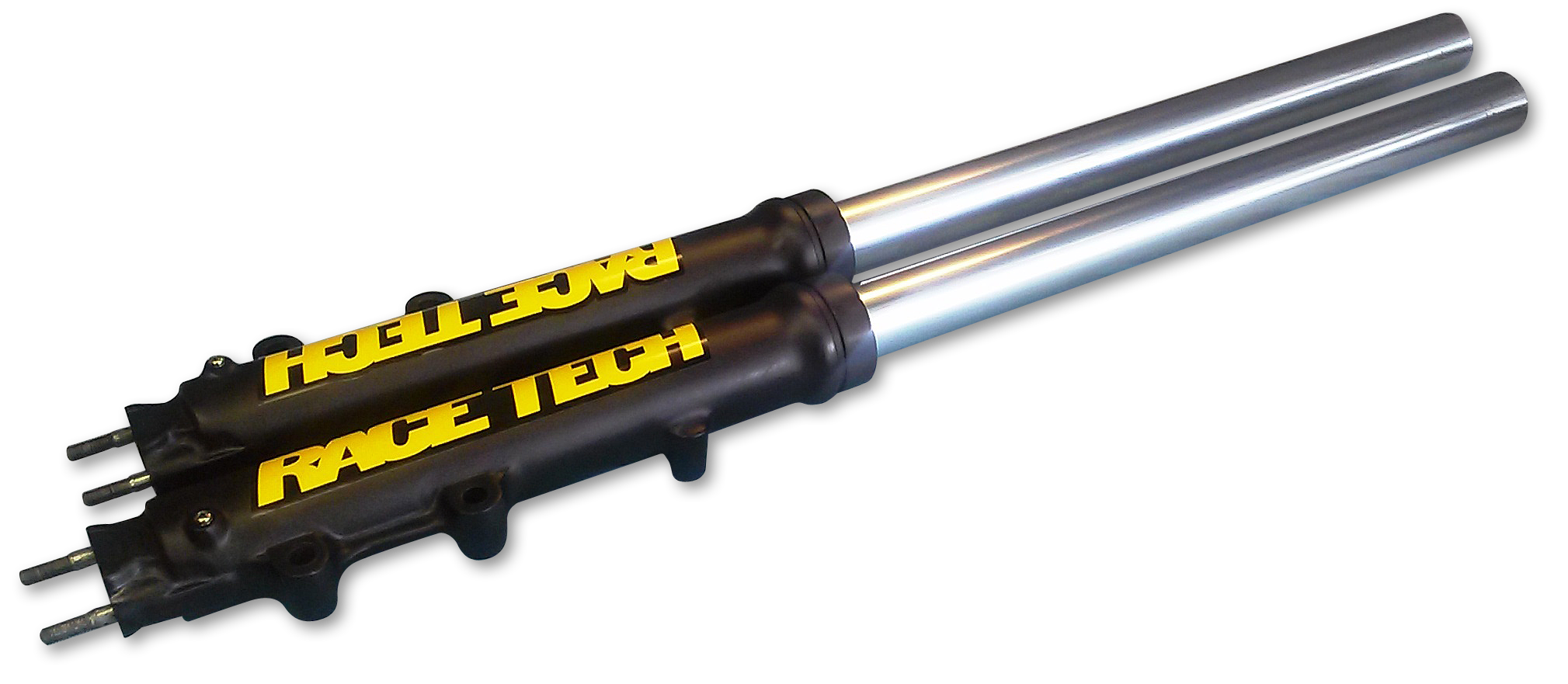

Fork Tube and Shock Body Hard Anodizing

Many of today's stock inverted forks come with the aluminum outer tubes hard anodized from the factory. Unfortunately the coating on many of them is very thin. In fact, some wear through in less than 10 hours of riding. Some forks, particularly conventional right-side-up forks, come from the factory with no hard anodizing at all. Vintage Motorcycle Forks & Shocks are not hard anodized and often lack bushings making this process even more critical. Vintage shock bodies can be ruined due to lack of service combined with lack of hard anodizing. The problem is, when the hard anodizing is worn through the bushing is riding on soft aluminum. The soft aluminum creates excessive friction. Vintage Forks may not even have bushings worsening the problem. Additionally excessive aluminum contamination of the oil occurs greatly increasing wear. The Hard Anodizing we offer is very high quality making the inside of the tube slippery simply due to its hardness greatly reducing friction! Another benefit of Hard Anodizing is its excellent resistance to wear. An aluminum shock body that has been Hard Anodized will wear like steel. This process will extend service life of the suspension fluid significantly due to less metal contamination. NOTES:

|