FORK GOLD VALVE INSTALLATION

|

|||||||

|

|

Tools Required

- In-lb torque wrench that accurately measures 0 to 50 in-lbs (0.58 kgf-m) (SnapOn Digital Torque Wrench shown)

- Hi-Strength Loctite

- Metric calipers and micrometer

- Drill

|

||||||

|

THE COMPRESSION ONLY CARTRIDGE

|

|||||||

|

|

DVS Setup Sheet - This example says Comp Right, Reb Left. This means the right leg contains the Compression Only Cartridge.

The first row lists the shim stacks for the Compression Only Leg.

The first shim stack in the first row labeled "Compression" is for the Base Valve at the bottom of the cartridge.

|

||||||

|

|

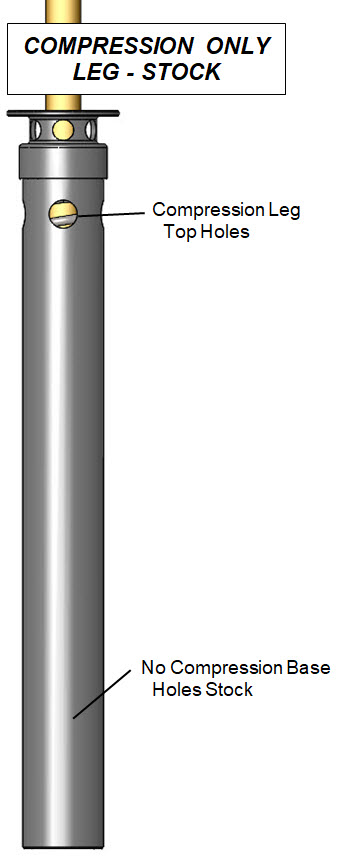

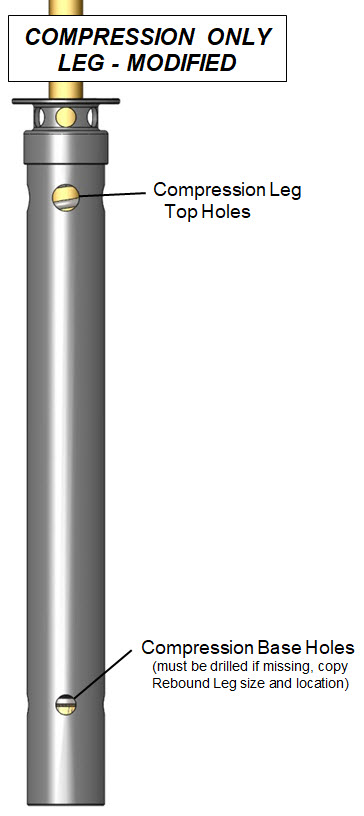

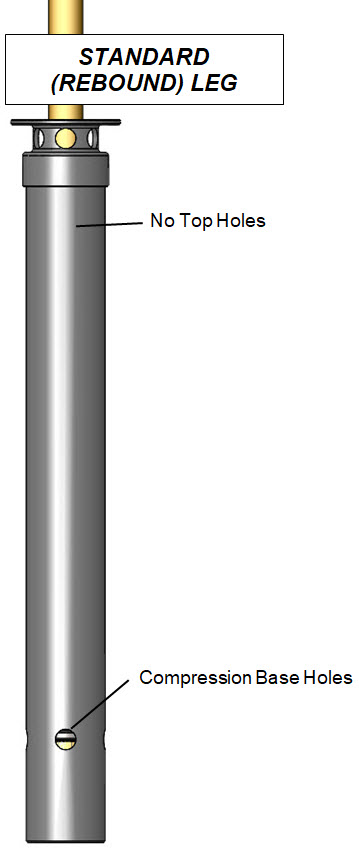

VC1- The Compression Only Leg is the one with the Top Holes.

Disassemble the cartridge.

Compression Base Holes - In many cases there are no Compression Base Holes. If they are missing they will need to be drilled.

If missing, the cartridge will need to have Compression Base Holes drilled near the bottom. Copy the Rebound Leg Cartridge for hole size and location. Deburr the holes.

|

||||||

|

|

|||||||

|

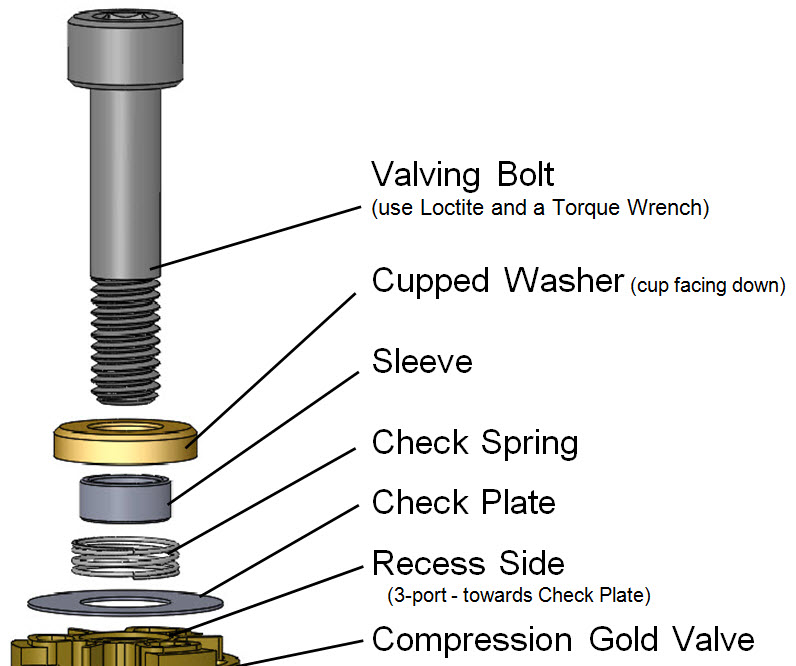

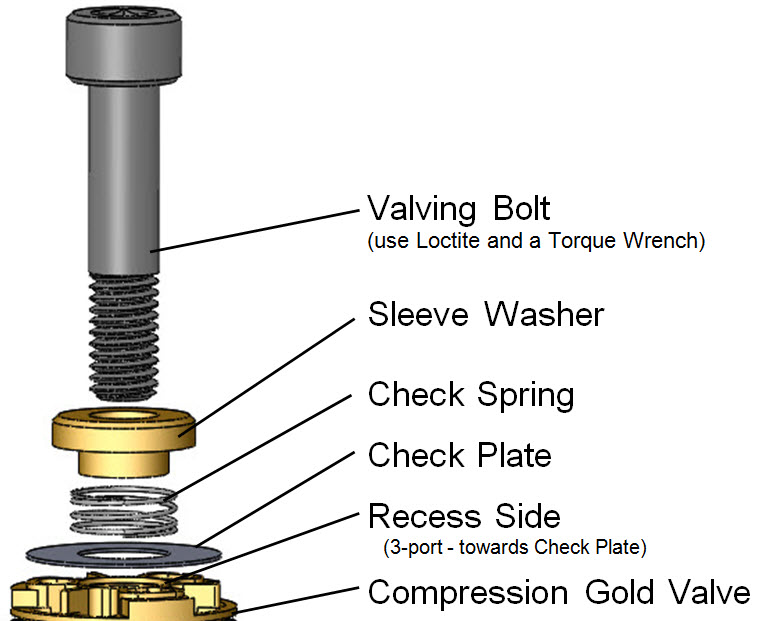

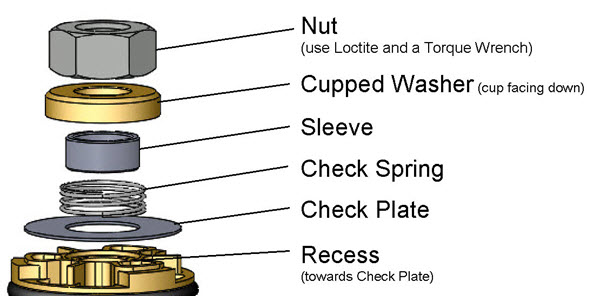

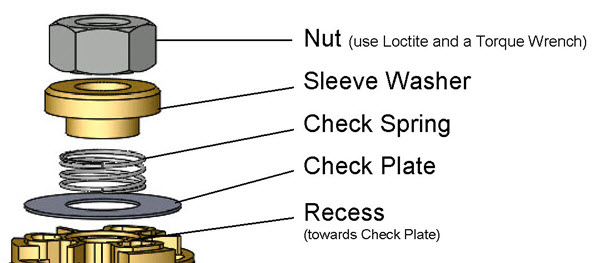

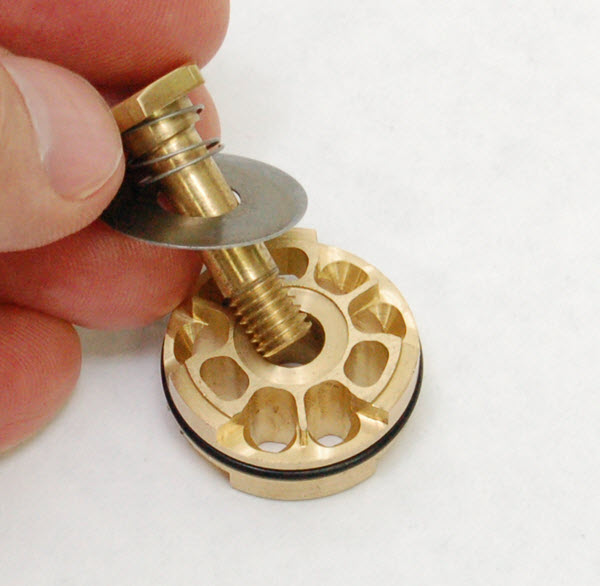

Base Valve Hardware Variations - Lots of possibilities, all similar.

|

|||||||

|

|

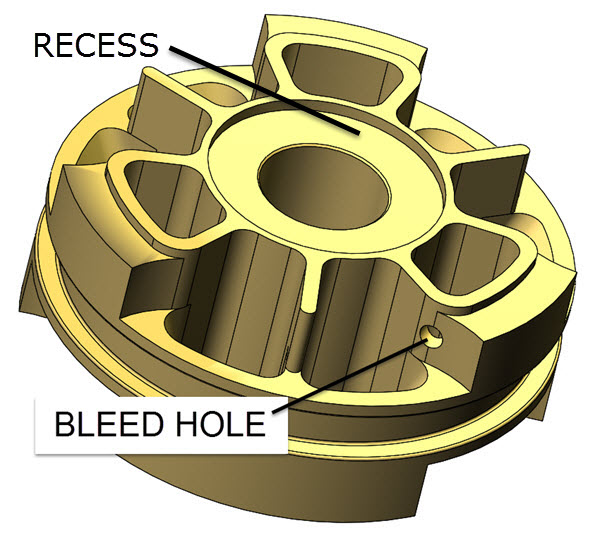

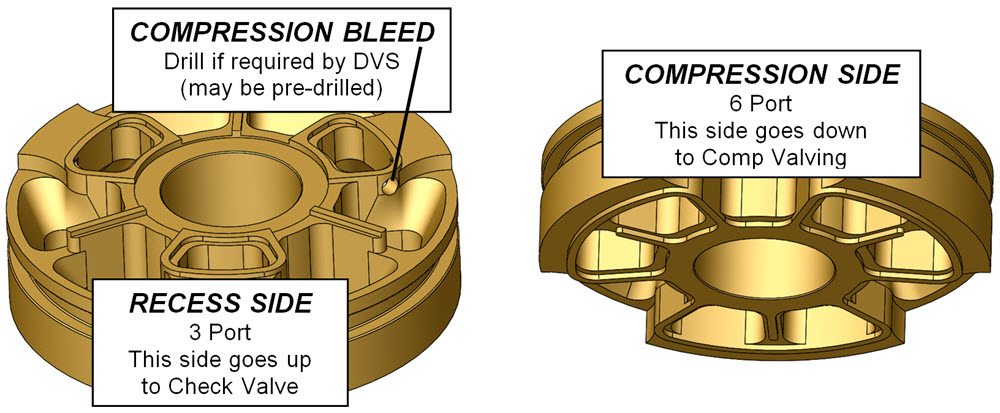

VC4- COMPRESSION BLEED HOLE

The Compression Only Base Valve Piston usually does not have a Bleed Hole.

Note: The Standard Rebound Compression Base Valve (the other leg) requires a bleed.

|

||||||

|

|

|||||||

|

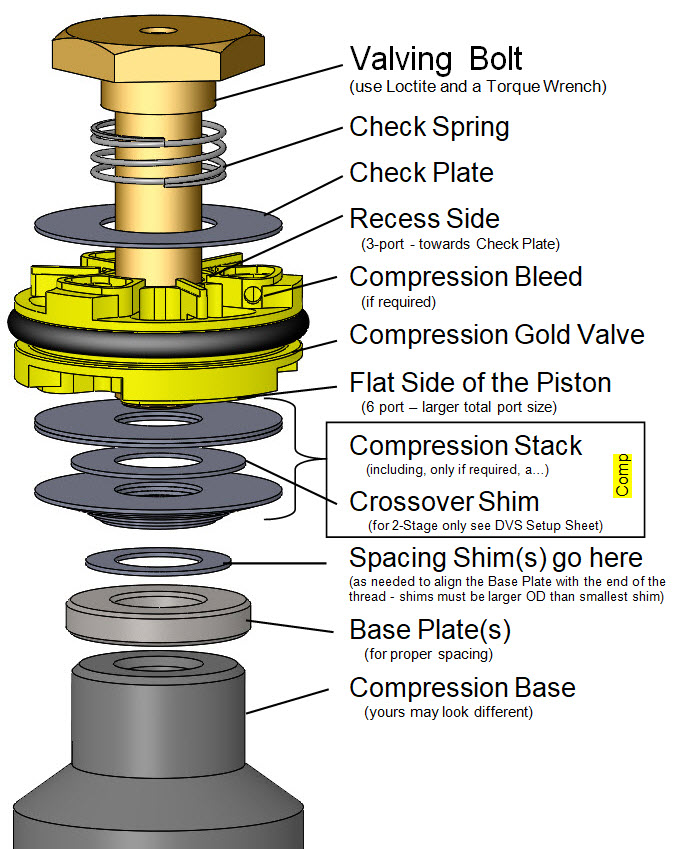

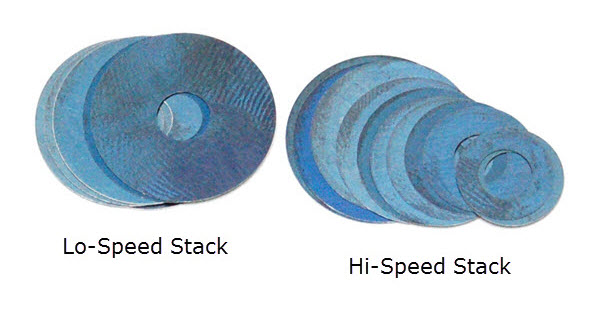

VALVING STACK TYPES - SINGLE OR TWO STAGE

VC5- You will either be building a Single Stage or a Two Stage Stack. The difference is the Crossover. The Crossover is a smaller diameter shim between the Lo-Speed and the Hi-Speed Stacks. Note: The DVS Custom Setup Sheet displays individual shims and does not label Hi-Speed, Crossover, and Lo-Speed. This is for your information only. Also you will not use all the shims provided in the Gold Valve Kit.

|

|||||||

|

|

VC6- Example - Two Stage

(Single Stage is exactly the same except there is no Crossover) Put the valving on the shaft in the order listed, starting with the Lo-Speed Stack.

For Two Stage the total valving stack is made up of a:

Lo-Speed Stack

Crossover

and a Hi-Speed Stack

|

||||||

|

|

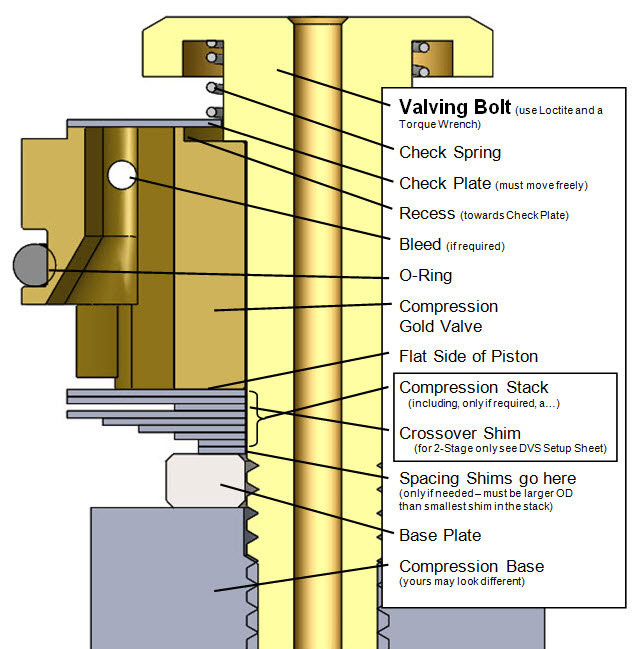

VC7- Place the Base Plate (thick washer) on the shaft.

|

||||||

|

|

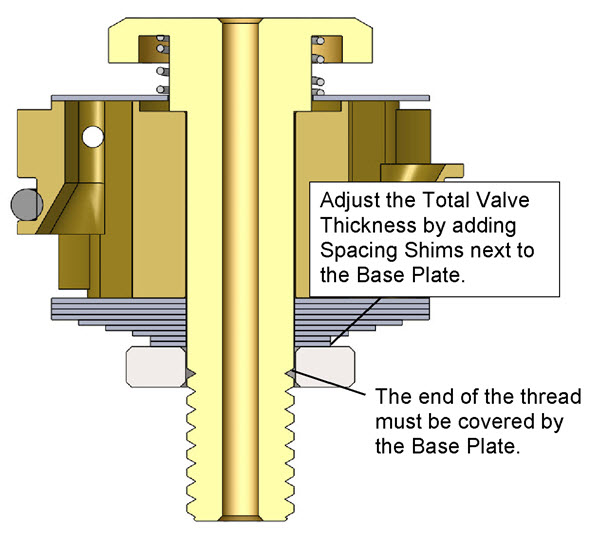

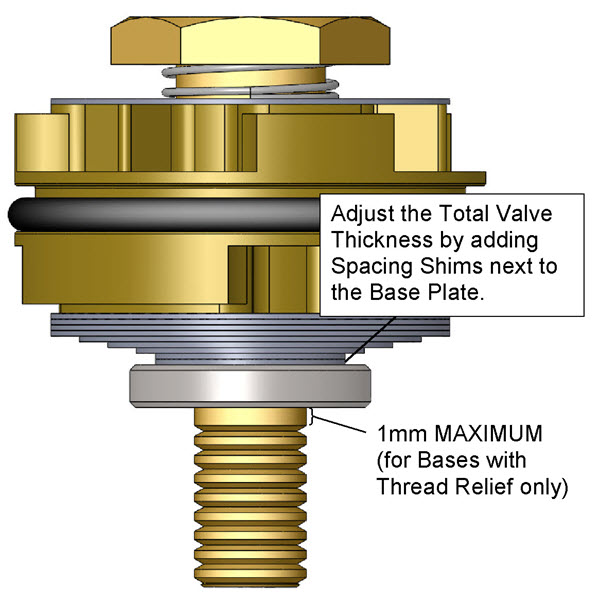

VC8- Make sure the Total Valving Stack Height is correct.

This step is here to insure you don't "run out of thread" when tightening the Valving Bolt. This height adjustment is done with Spacing Shims. If needed, they should be added just above the Base Plate. The Spacing Shims must be larger in diameter than the smallest shim in the stack.

The shims should be guided with the straight, non-threaded part of the shaft and should not be on the thread.

This particular Compression Base has a 2mm "non-threaded" pocket in it for bolt thread clearance. (Most Bases do not have this pocket.) Normally when the valve stack is compressed upon install, the thread cannot extend below the Base Plate.

With this pocket the thread can extend slightly (1mm max) beyond the Base Plate.

|

||||||

|

|

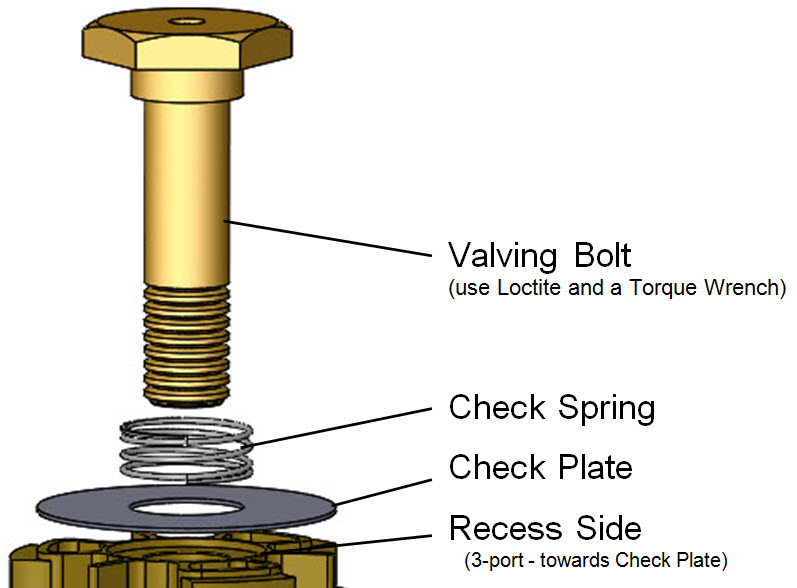

VC9- Use Loctite on the Compression Base thread.

Note: Notice the thread relief in this particular base (not all have this feature).

|

||||||

|

|

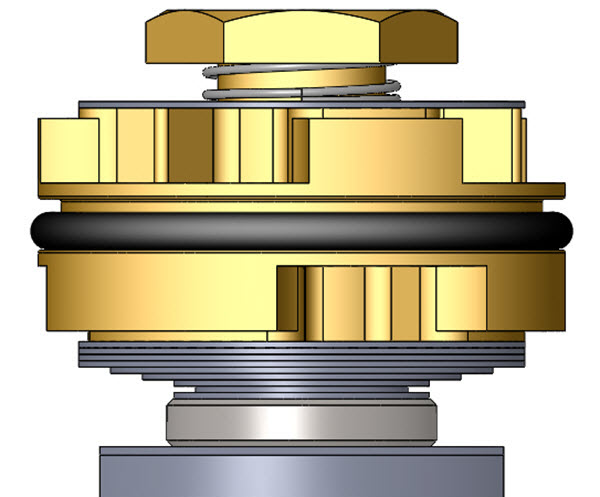

VC10- Make sure the Base Plate is installed, then install the Valving Bolt and...

|

||||||

|

|

VC11- tighten it to spec with a torque wrench.

CAUTION! The threads can be damaged without extreme care. You must use Loctite. The 6mm bolt must be torqued with a torque wrench to 30 in-lbs (2.5 ft-lbs or 0.35 kgf-m), NO MORE! Do not take this step lightly. |

||||||

VC12- Single Stage |

|||||||

|

|

VC13- Make sure the Check Plate is free and can move up and down against the Spring.

|

||||||

|

|

VC14- Visually check your work.

Hold the Compression Stack up to the light and look for proper assembly. If there are any problems, disassemble the stack and look for burrs to surface and/or dirt in the valving. Reassemble and check again.

Make sure the o-ring is on the Gold Valve.

|

||||||

|

|

VC15- Make sure the shims that go next to the Gold Valve completely cover the ports on both sides of the piston! If the ports are not covered there will not be enough damping.

This could be caused by a number of reasons. Please call Tech Support if this occurs and you can't figure it out.

|

||||||

|

COMPRESSION ONLY - REBOUND ROD VALVE

|

|||||||

|

|

VR1- Put the rebound rod in the shaft holding tool and remove the peening by filing it down to the nut face.

Remove the rebound valving nut and valving assembly.

|

||||||

|

|

VR2- Chamfer the end of the thread lightly. Use a wire wheel to smooth it further.

|

||||||

|

|

VR3- Blow air through one of the side holes while covering up the other side hole. This allows any fillings that may be in the shaft to be removed through the top hole.

Your Rebound Holder may not look like this but you get the idea.

|

||||||

|

|

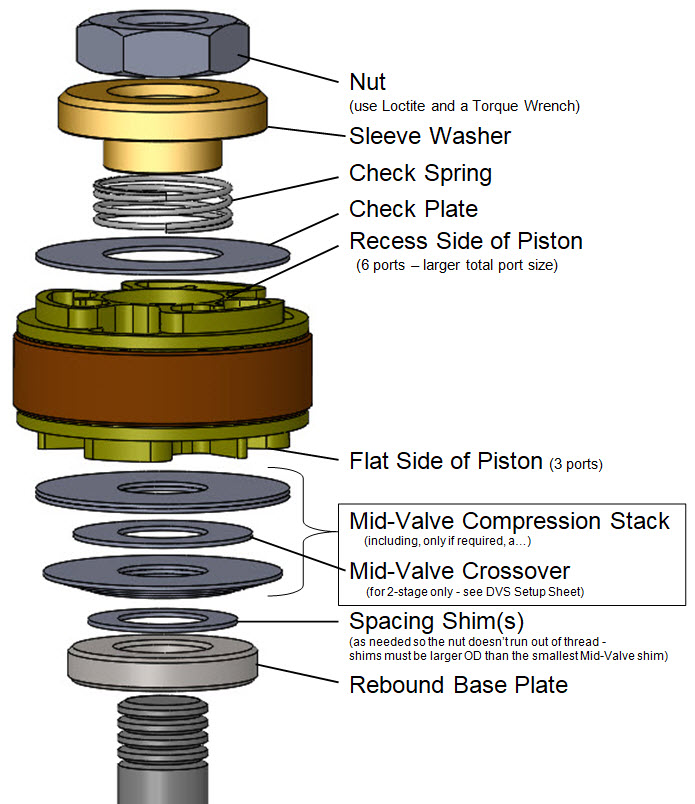

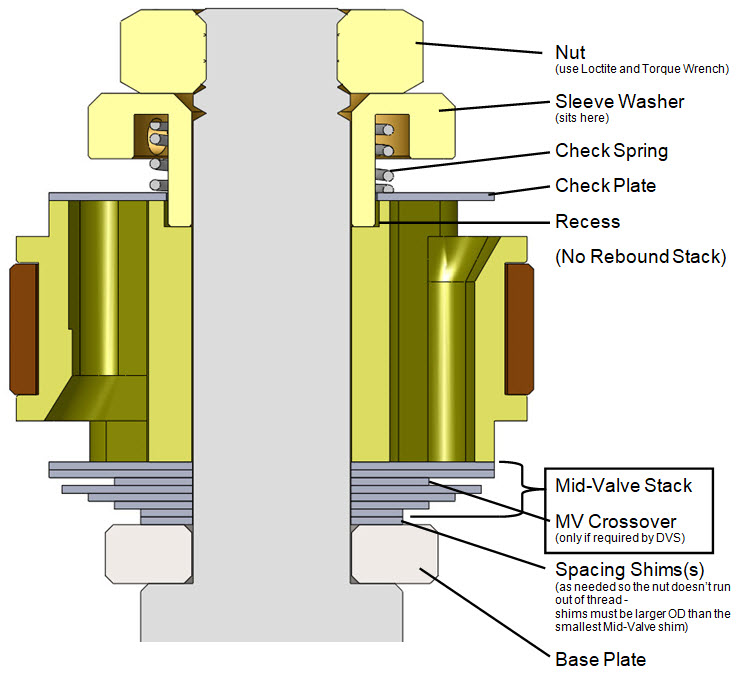

VR4- MID-VALVE STACK

First install the:

Base Plate

Assemble the Mid-Valve Stack recommended by the DVS onto the Valving Shaft. It may be single stage or two stage.

|

||||||

|

|

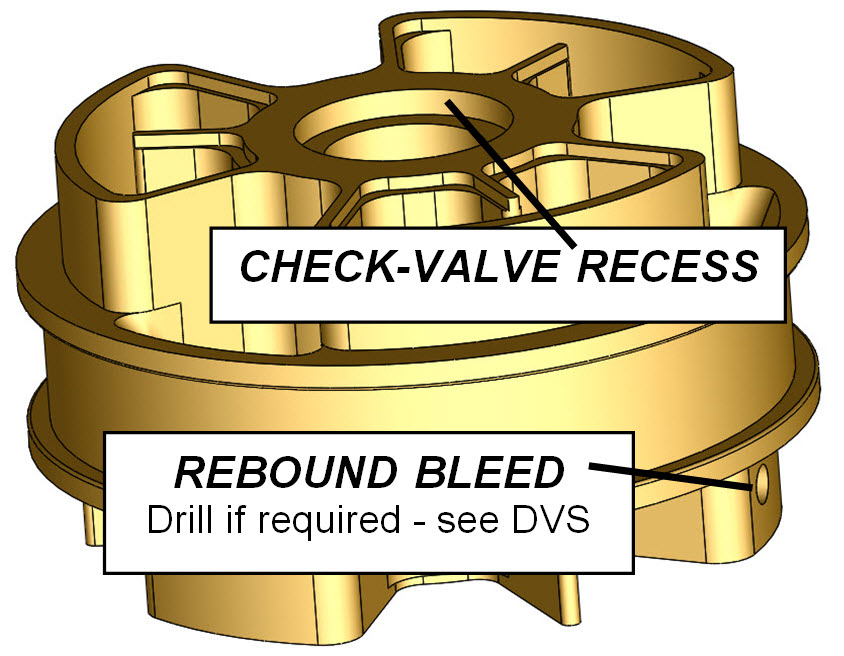

VR5- REBOUND BLEED HOLE

Skip this step if the DVS does not call for a Rebound Bleed.

If your DVS Setup Sheet calls for a Rebound Bleed Hole check to see if there is one already pre-drilled in the piston. If one is called for, and there is no pre- drilled bleed hole, you will need to drill one.

Notice that the bleed hole is on the opposite side of the piston with the Recess and is drilled sideways. The exact location is not critical.

|

||||||

|

|

VR6- Install the Rebound Gold Valve WITH THE RECESS IN THE GOLD VALVE FACING UP TOWARDS THE CHECK PLATE.

REBOUND STACK

There is no rebound stack. It is a Check Valve on this leg.

|

||||||

|

VR7- Make sure the Total Valving Stack Height is correct so you get full thread engagement and do not run out of thread. Critical!!

This step is here to insure you don't "run out of thread" onto the straight, non-threaded, portion of the shaft when tightening the Nut and the Nut gets full engagement.

If needed, height adjustment is done with Spacing Shims added just below the Reboud Base Plate.

Spacing Shims must be larger in diameter than the smallest shim in the stack. Sometimes this is best accomplished by adding additional Base Plates.

|

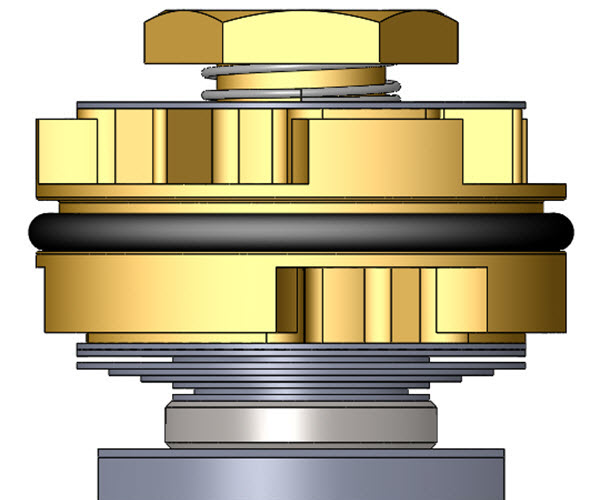

|||||||

|

|

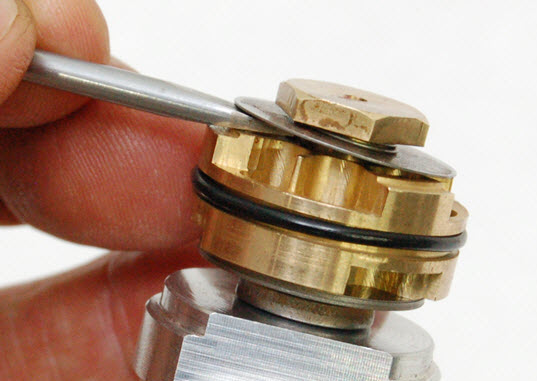

VR8- TIGHTEN THE COMPLETE ASSEMBLY

Make sure there is Loctite on the thread of the shaft. Make sure the mid-valve is free to move up and down. Tighten it to spec with a torque wrench.

CAUTION! The threads can be damaged without extreme care. You must use Loctite.Most 6mm bolts must be torqued with a torque wrench to 30 in-lbs (2.5 ft-lbs or 0.35 kgf-m), NO MORE!Check your DVS Setup Sheet. Do not take this step lightly. |

||||||

|

|

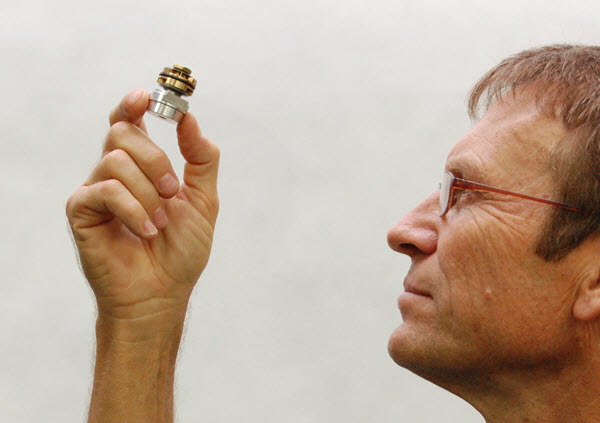

VR9- Check your work. Hold the valve assembly up to the light and look for proper assembly. If there are any problems, disassemble the stack and look for burrs to surface and/or dirt in the valving. Reassemble and check again.

|

||||||

|

|

VR10- Make sure the shims that go next to the Gold Valve completely cover the ports on both sides of the piston! If the ports are not covered there will not be enough damping.

This could be caused by a number of reasons. Please call Tech Support if this occurs.

|

||||||

|

|

|||||||

|

|

Next setup the Standard (Rebound) Leg

VR11- Follow these links for instructions for Compression and Rebound.

|

||||||

| • Single Stage - made of: Lo-Speed Stack Hi-Speed StackThere is NO Crossover (it becomes one stack.) |

|

|

| • Two Stage - made of: Lo-Speed Stack Crossover Hi-Speed StackThe Crossover Gap is visible |

|

|