RACE TECH HI-PERFORMANCE

|

|

|

|

Disassembly D1 Clamp Shock into a vise with Soft Jaws. D2 Loosen Lock Ring. D3 Remove all spring preload using a Spanner Tool or by loosening the Collar by hand. D4 Clean and lube the threads.

|

|

|

Disassembling the Retaining Collar

D5 Use a small Screwdriver or similar tool. Find the opening in the plastic Dust Shield and gently pry the Bottom-out Bumper away from the end of the Shock approximately 50mm (2”).

D6 Use a Hydraulic Spring Compressor to compress the stock spring and remove the Spring Retaining Collar.

D7 Remove the stock spring and Dust Shield.

*Note*

The Honda TRX450R front shock requires the spring to be compressed approximately 25mm (1”) to safely remove the stock spring. A Mechanical or Hydraulic style Spring Compressor should be used to safely remove the spring. Many suspension shops have a spring compressor such as this. If you are unable to find a shop in your area please feel free to contact Race Tech for details on purchasing a spring compressor. You can also send your shocks to Race Tech and we will be happy to install the Spring Kit for you.

|

|

|

NPL Collar and Spring Kit Assembly A1 Remove the stock Preload Adjuster Assembly and replace it with the NPL Collar locating the tabs into the slots. “Preload” will no longer be adjusted with an adjuster ring. You will adjust the NPL Gap and Crossover with Crossover Rings. (See NPL Gap Setup) A2 Install the NPL Spring (the softest spring). Next install the Short Go-Between orienting the longer of its two flanges into the NPL Spring. |

|

|

A3 Install the Secondary Spring (larger wire diameter than the NPL Spring). Install the Standard Go-Between with the long flange going into the Secondary Spring.

|

|

|

A4 Install the Main Spring and the new Lower Spring Retainer. Don’t use the stock Lower Spring Retainer or Dust Shield. Next Setup the NPL Gap. You will need to remove the spring again to do this.

|

|

|

Tuning Options

A5A stacked spring can provide a progressive spring rate. When the shock compresses and the Go-Between flanges touch, the spring rate gets stiffer. Adding Crossover Rings decreases this Crossover Distance and makes the system stiffer earlier in the travel.

Crossover Rings can be inserted between the Go-Between flanges extending into the Secondary Spring. The two main reasons for adding Crossover Rings are excessive body roll and bottoming-out.

Crossover Rings are provided in ⅛”, ¼” and ½”.

A6 Some of the Crossover Rings included in the kit will be used to set up the proper NPL Gap.

Refer to the DVS Specs at www.racetech.com to get the recommended Crossover distance for your application (you don’t need an Access Code to get spring setup specs).

|

|

|

NPL Gap Setup

A7 Refer to the DVS Specs from racetech.com.

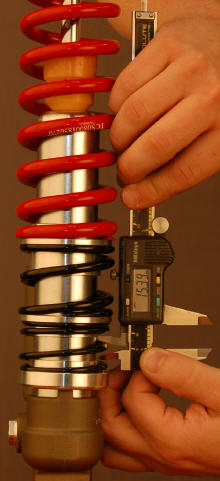

A8 Measure the distance between the NPL Collar flange and the Short Go-Between flange extending into the NPL Spring. This is the NPL Gap.

A9 Use the Crossover Rings to achieve the proper NPL Gap called out in the DVS specs.

*Note*

NPL Gap determines the ride height of the ATV. A larger Gap creates a lower ride height; a smaller Gap equals a higher ride height.

|