SHOCK SHAFT REBUILD - BFRC SHOWA

|

|

|

|

Tools

- Torque wrench (SnapOn Digital Torque Wrench shown)

- Metric calipers and micrometer

- TMVJ 065 Vise Jaws mounted on a Vise - suggested - TSSB 16 - for Seal Head installation - TSPA 01 - Shock Preload Adjusting Tool

- TFSD 46 - Fork Seal Driver Supplies

Contact Cleaner - or other good, clean solvent

Loctite - Hi-Strength (included in the Gold Valve Kit)

USSG 01 - Ultra Slick Seal Grease

|

|

|

|

|

|

|

|

|

3 - This is the Seal Head detached from the Damping Tube. Slide the damping tube off.

Notice the end of the cartridge tube with the holes is closest to the seal head.

|

|

|

4 - The nut on the end of the shaft is peened on. You can turn off this peening on a lathe or you can grind it off with a porting tool.

|

|

|

5 - Remove the piston and slide the shaft out of the seal head. Deburr the end of the shaft. You will re-use the stock nut.

|

|

|

6 - Reassemble the shaft in reverse order. Use a Bullet Tool (TSSB 16) to protect the seal. Use High-Strength Loctite and torque the nut to 25 ft-lbs (34 NM).

|

|

7 - Press fitting the seal head into the tube will occur automatically during reassembly.

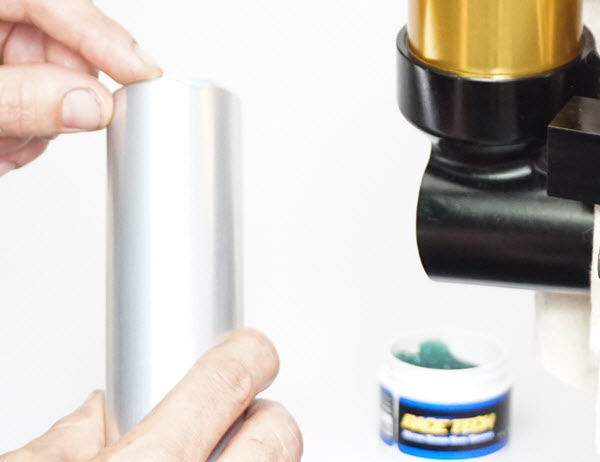

Put a small amount of Ultra Slick Seal Grease on the outer edge of the inner tube to lube the o-ring in the shock.

|

|

|

8 - Install the inner tube into the shock body with the holes up.

|

|

|

9 - Insert the shock shaft assembly into the inner tube.

|

|

|

10 - Use the Seal Head Setting tool and push the seal head down as far as you can. It will need to go further as the seal head is press fit into the inner tube.

|

|

11 - Invert the shock. Rest the Seal Head Setting Tool on the vise jaws in the "V". Use a plastic mallet and tap on the end of the shock body to seat the seal head.

Install the circlip completely into the groove.

Return to the Shock Rebuild Instructions BFRC to complete the assembly.

|

|