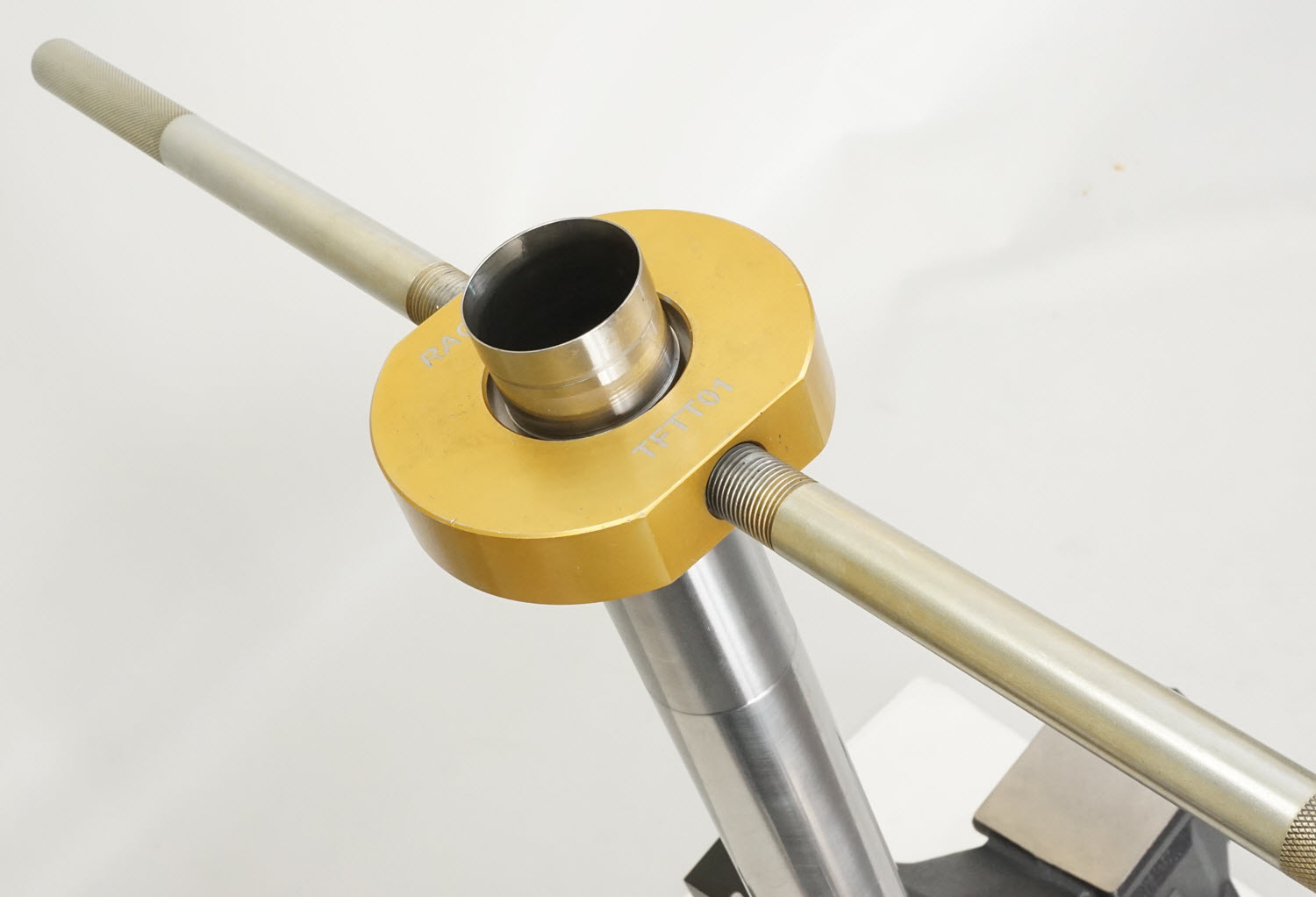

FORK TUBE TOOL | |

This 2 Pin tool works with most fork tubes. | |

| Many fork bottoms have a set screw that must be removed. Some are "staked" and must be partially drilled. The set screw often deforms the thread in the fork tube so much that when the fork tube is unscrewed it destroys the thread in the fork bottom. To avoid this you can use a flat end mill or porting burr to remove the deformed thread. Be careful that you do not go through the tube wall. In many cases you can switch the fork tube left for right so the deformed area doesn't line up. You may want to drill and tap the set screw hole to the next larger size. | |

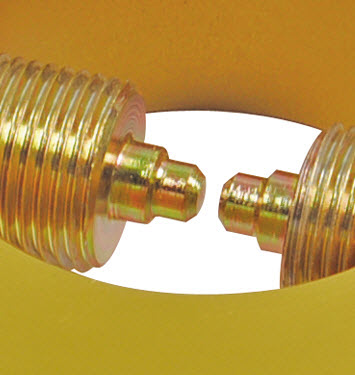

The pins in the tool will be inserted into the holes in the fork tube. The pins have two diameters available. Use the larger one if it fits. | |

Securely clamp the fork bottom and unscrew the fork tube. It is often helpful to heat the aluminum fork bottom to 375 degrees F to loosen the thread lock. Use Hi-Strength Threadlock and tighten securely. Re-install the set screw. | |